3.1 PurePack Chemical Treatment Technology

PurePack Chemical Filtration Technology

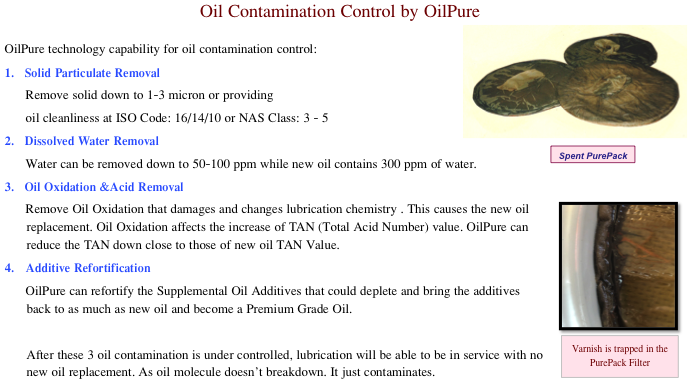

PurePack FIlter Media is made of powdery solid, organic material, 100% Organic, Biodegradable and Food Grade. Spent PurePack will decompose in nature when disposal. There are over 30 different PurePack materials in different density and is formulated into PurePack formula for customize the decontamination oil problems with different PurePack solutions. There are 3 or 5 layer PurePack that can absorb chemical contamination from most dirty oil.

PurePack media is capable of removing Solid Particle when dirty is flowing through, Dissolved Water and Oil Acidity from Carboxylic Acid or Lewis Acid that has Hydrogen molecule inside. These acids are determined in Total Acid Number (TAN) These are the input or cause of Varnish or Oil Oxidation By-Products problems. PurePack media has no negative effect on existing oil additives. In other words, PurePack absorbs acids but doesn’t touch Oil Additives in the oil.

While Fuller Earth or Clay have the ability to absorb acid from oil but they have positive effect on the oil. They strip the existing oil additives from the oil. Another problem from these earth materials, they may absorb acid from oil, but infuse minute solid particle from clay into the oil which is more difficult to filter, even 1 micron paper filtration.

Oil Acidity is the Root Cause of all Varnish and Oil Oxidation-by-Products. The available filtration of Varnish using Low Oil Temperature Filtration will not really solve Varnish problems because it fixes the Cause, but not the Root Cause. Sooner or later these Varnish and Oxidation-by-Products will come back in the next few months because Oil Acidity is still Omnipresence.

Oil Applications for OilPure

- Hydraulic oil

- Gear oil

- Transformer oil

- Compressor oil

- EDM oil

- Turbine oil

- Transmission oil

- Synthetic oil

- Fire Resistant oil

- Phosphate Ester oil

- Cutting oil

- Quenching oil

- Drawing oil

- Vacuum oil

- Honing oil

- Grinding oil

- Insulating oil

- Spindle oil

- Metal rolling oil

- Spindle oil

Customized Oil Purification System

- Solid Particle Removal – PurePack can remove particle having 1-3 micron or keep the oil cleanliness at ISO Code 16/14/10 or NAS Class 3-5.

- Dissolved Water Removal – PurePack can remove dissolved water from 1,500 ppm down to 50-100 ppm while new oil usually contains about 300 ppm of water.

- Oil Oxidation & Acid Removal – PurePack can remove Oil Oxidation that causes chemical changes in the oil. Oil Acidity will increase during oxidation process. PurePack also removes Oil Acidity and reduce TAN Total Acid Number Value from oil, close to new oil TAN value.

- Additive Refortification – OilPure can formulate and refortifies Supplemental Oil Additives that have been missing or depleted in service. So the purified oil can be as good or better than new oil or even upgrading to a Premium Grade lubrication.

If Three Oil Contamination Control: Solid Particle; Water; and Acidity are under controlled as well as replenishing oil additives, This industrial lubrication can be reused for decade. No need to change new oil as oil is not contaminated. Oil molecule never breakdown.

PurePack changes powdery solid status to become Crystal Pack when soaking with oil. PurePack is no longer in powder form. PurePack becomes very porous and act as media to cluster all different dirt sizes to be collected inside. So Dirt will filter more Dirt. Porous PurePack has High Surface Area and allow Higher Dirt Holding Capacity, 30-40 times more than Pleated Paper Filter. So there is no Micron Rating or Beta Ratio for PurePack.

Since PurePack is made of 100% Organic materials, there is no Electrostatic Charge occurred in the filter media as compared to Pleated Paper Filter, causing oil oxidation in the oil.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815 • WhatsApp: 1-913-522-0272

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.