3.11 OA-1 On-Line Oil Analyzer

On-Line Oil Analyzer – Oil Monitoring System – Machine Condition Monitoring System

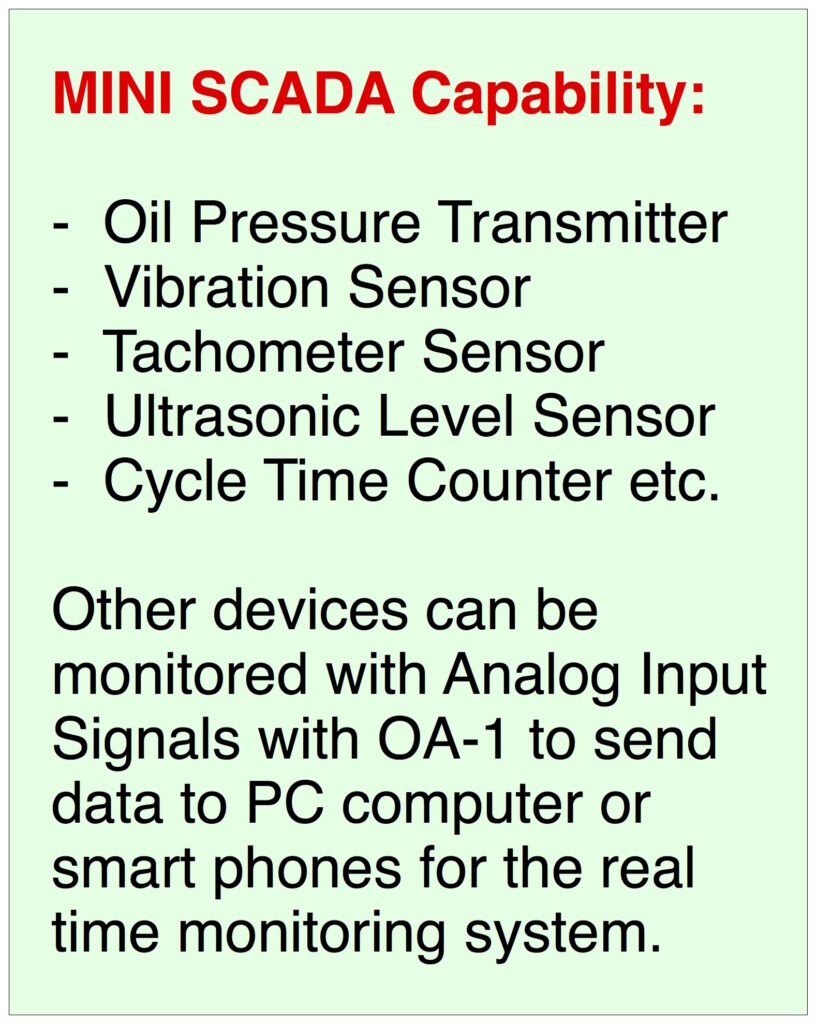

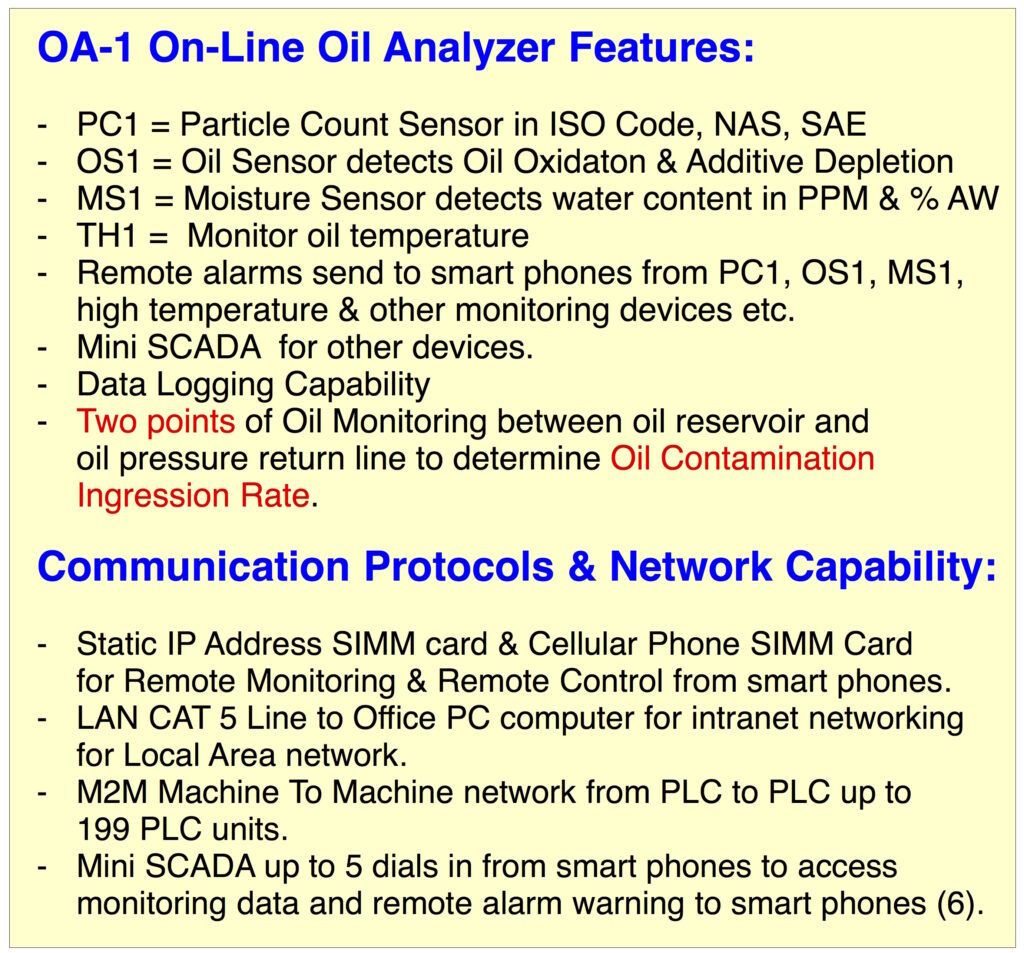

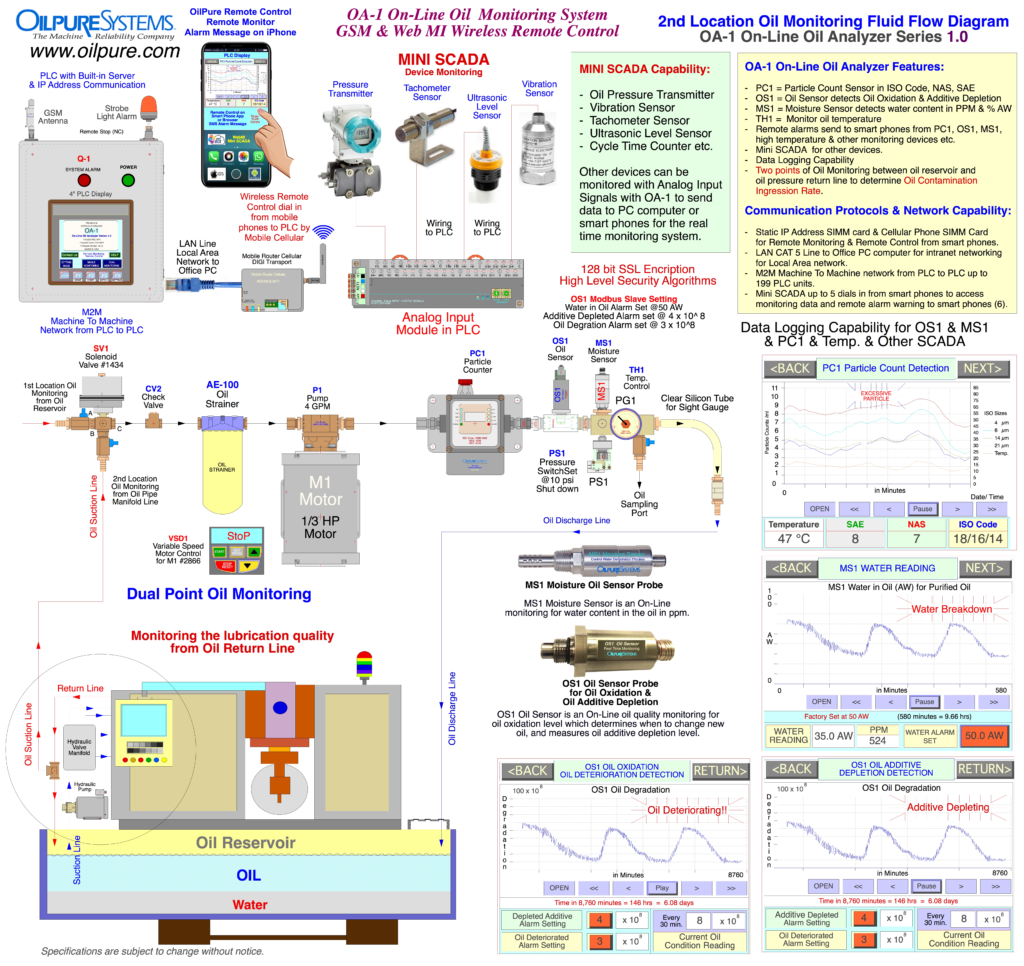

OA-1 On-Line Oil Analyzer with IIOT4.0 Wireless Remote Monitoring & Remote Control Mini SCADA from OilPure is the On-Line oil testing device that reads oil contamination and additive depletion on a Real Time basis for 24 hours – 365 days. The OA-1 will determine the changes in lubricating properties and assimilate the Characteristic and Behavior of machine lubrication.

This data will reveal Oil Contamination Ingression Rate that allows us to design the proper preventive control of the oil contamination that disrupts the machine performance. While the conventional oil analysis from laboratory is merely a guess work on a periodic basis. As saying in Six Sigma, What get measured, get controlled.

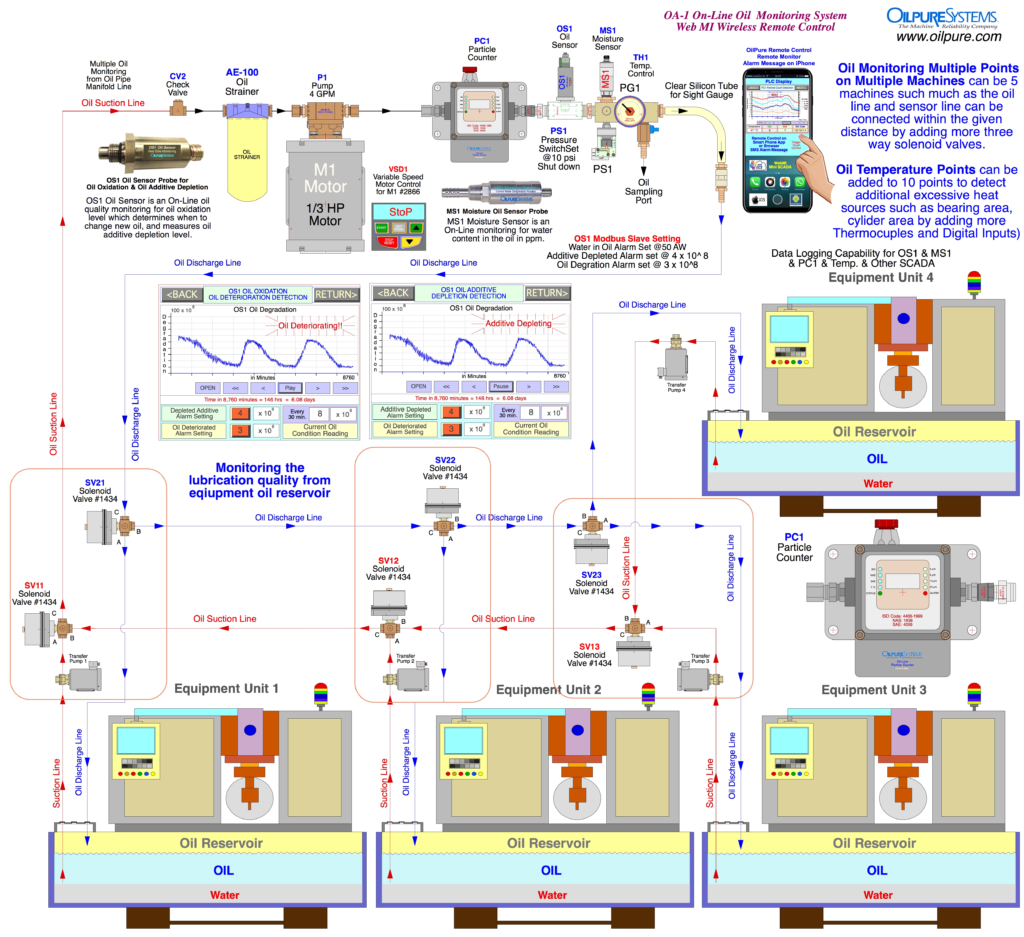

On-Line Oil Analysis OA-1 Oil Analyzer is design to reads oil contamination with Centralized System from Multiple Point Oil Location from single machine or multiple machines.

Tribology 4.0 is IIOT4.0

- Currently we are heading to Tribology 4.0 which the oil contamination control, oil oxidation level and oil additive depletion rate utilizes the Wireless SCADA with Centralized Control System to manage and monitor the changes of these variables. The study of these data changes allow us to better understand the Characteristic and Behavior of the Input Variances that lead us to the machine failures.

- Data collecting is gathered in Data Logging format which yields into Big Data. Using Data Analytics to develop the line of defense in Interactive Proactive that is responsive to problematic occurrence autonomously. This new approach will become a systemic automated operation that will by-pass human error in the process.

- It is the fact that human operator causes most maintenance and lubrication problems in the plant. This human factor must be avoided in such a way to improve efficiency and productivity. This autonomous system is described in the next slides of how the Tribology 4.0 should work for today industries.

On-Line Oil Analysis & Machine Condition Monitoring

- On-Line Monitoring System will collect lubrication data and shows the changing data in Delta (∆) Value as well as displays in Trend Analysis while the equipment is running Full Time. We will not only, acknowledge the lubrication quality but also, witness the changes in lubrication quality describing machine performance. These lubricating data reveals the Root Cause of machine problem and help us diagnose the Variance Input. This data will help us to set a Line of Defense in Proactive Preventive Maintenance Plan to improve Machine Reliability.

- Sending Oil Analysis to laboratory for testing is becoming obsoleted as it only detect lubrication quality at one point in time. One sampling for a month or 3 months provides inadequate oil data that can not represent the health of machine in the whole picture. So the result from lab Oil Analysis is just not enough to predict the real oil problems and find way to improve the process.

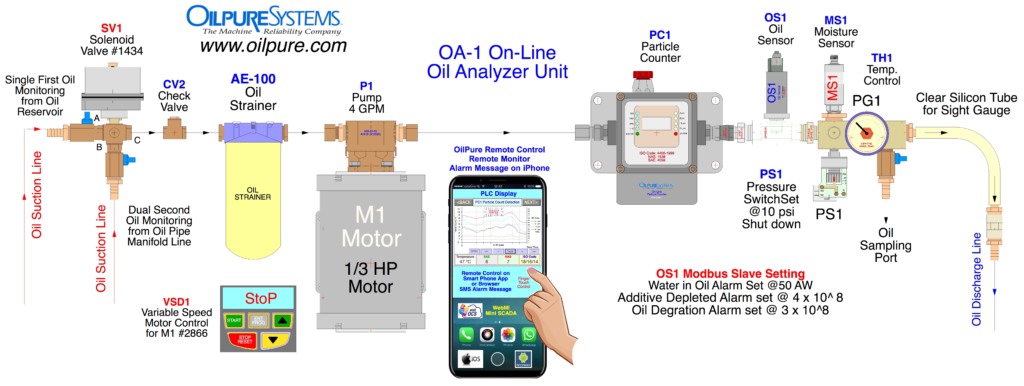

OA-1 Oil Analyzer Oil Flow Diagram

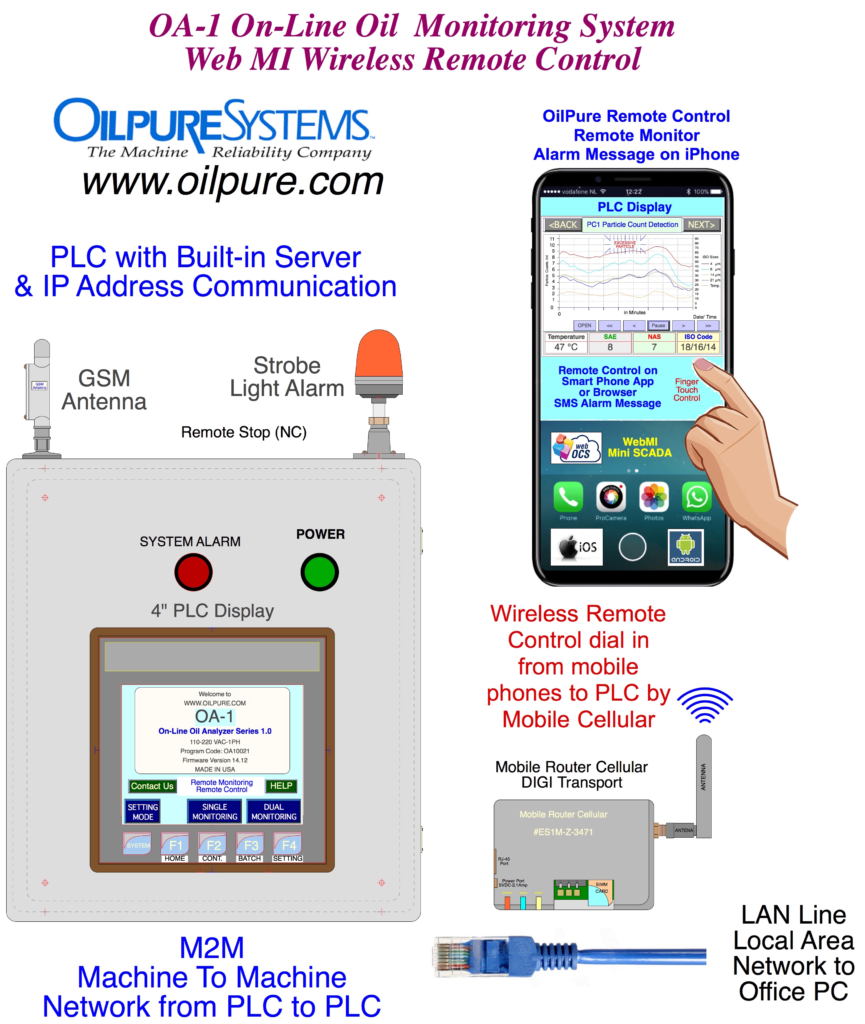

OA-1 wireless communication protocol

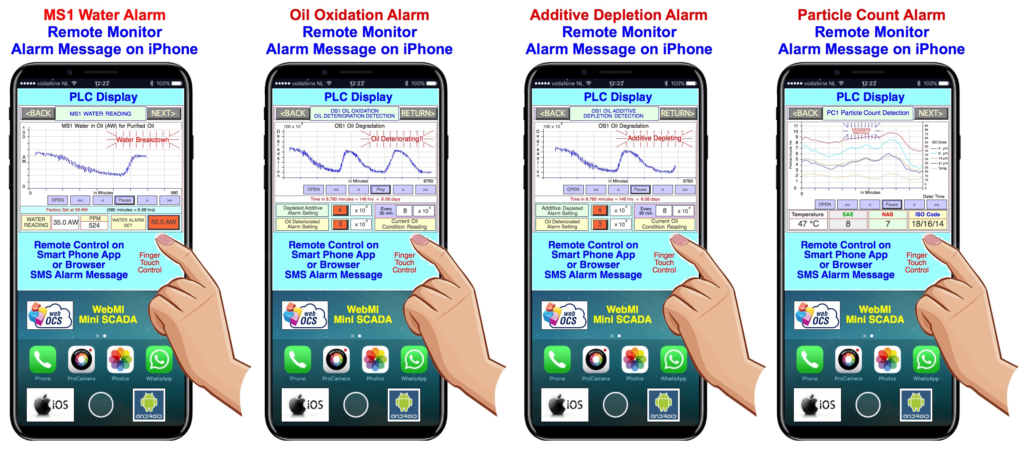

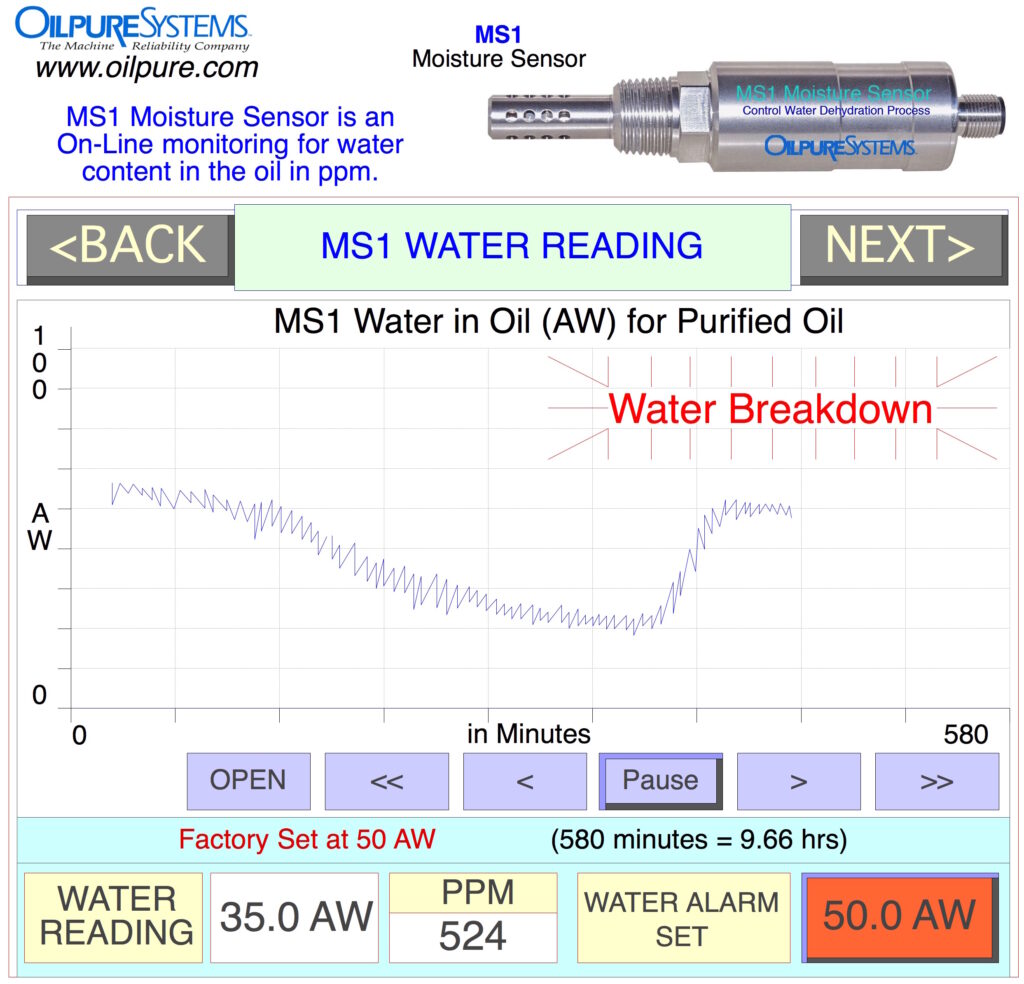

MS1 Moisture Sensor reads water in both ppm (Parts per million) and % AW (Water Activity). MS1 is also control Vacuum Jet Dehydration process to assure that the discharged oil has water less than 50-100 ppm or set ppm value in the MS1.

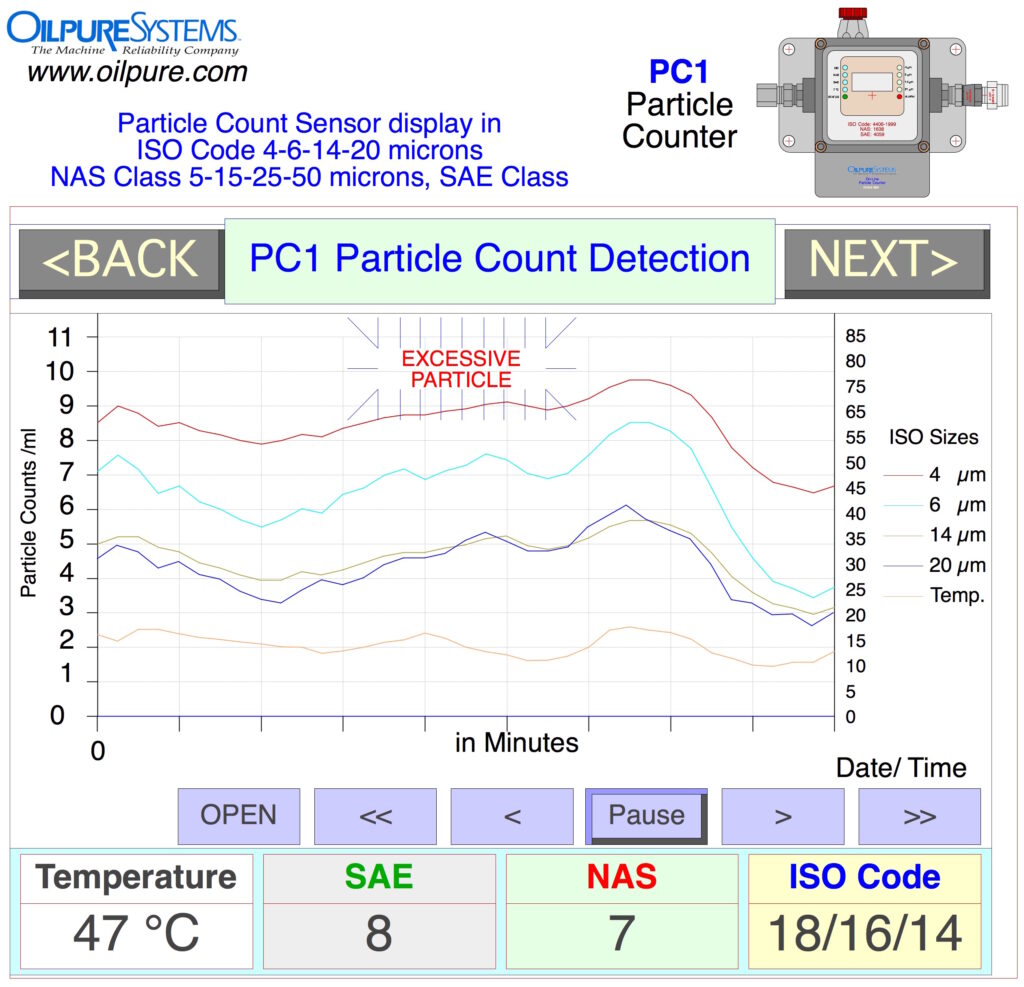

PC1 Particle Count Sensor reads particle in ISO Code, NAS, SAE standards. PC1 is used in the On-Line Oil Monitoring system.

MS1 Moisture Sensor reading display

PC1 Particle Count Sensor reading display (ISO 4406)

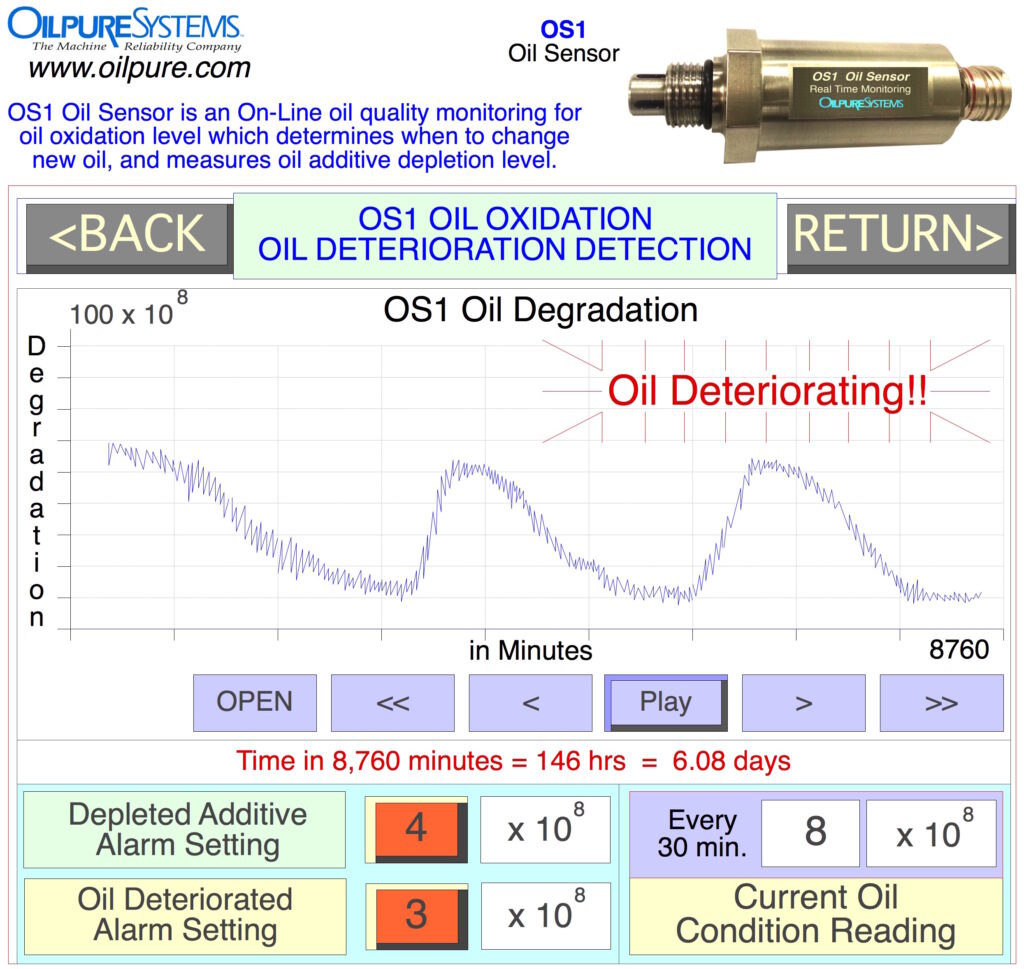

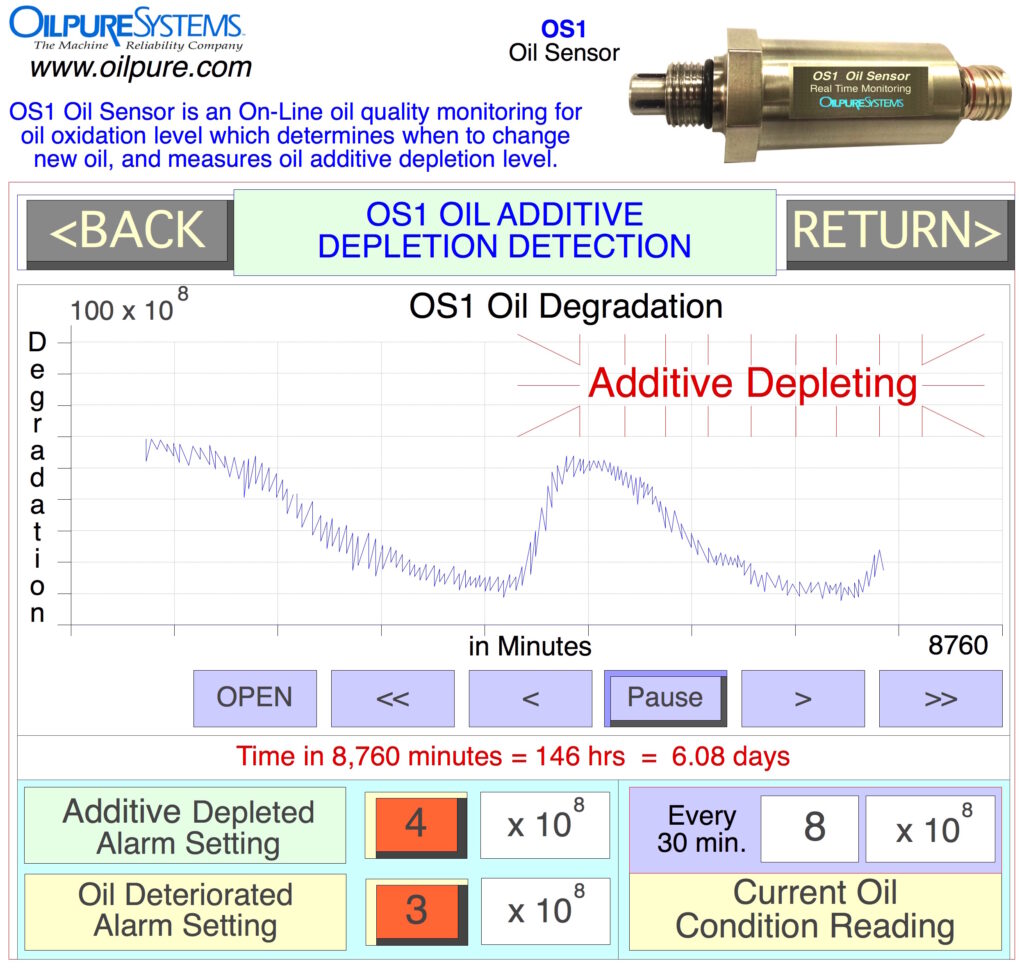

OS1 Oil Sensor detects the chemical changes in the oil and illustrate the increasing of Oil Oxidation and the decreasing in Depleted Oil Additive Level.

OS1 Oil Sensor reading display on Incremental changes in Oil Oxidation

OS1 Oil Sensor reading display on Incremental changes in Oil Additive Depletion

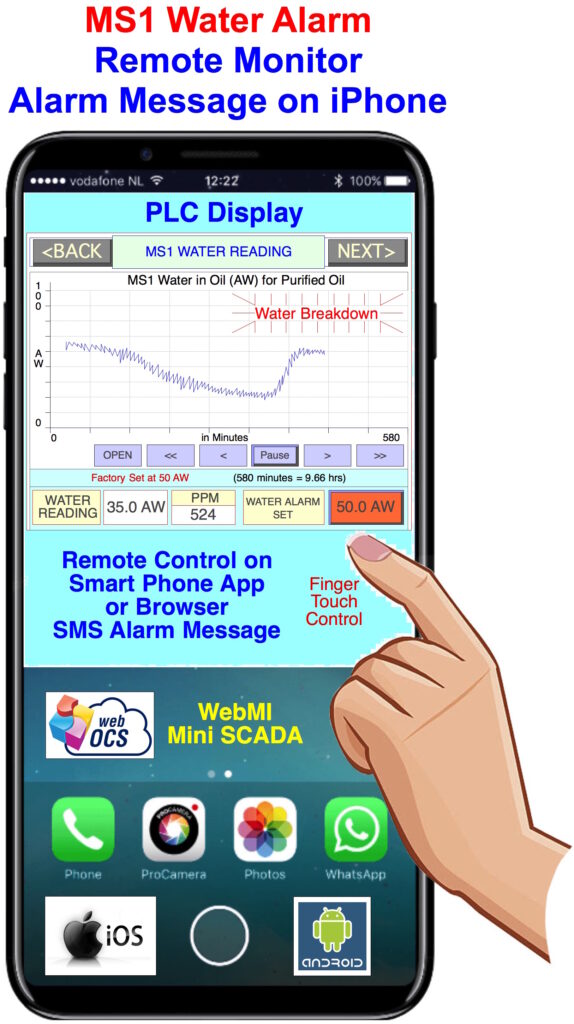

OA-1 On-Line Oil Analyzer with Machine Condition Sensors continuously keeps monitoring the equipment and reports the oil condition 24 hours/ 7 days, sending the alarm messages to operator by e-mail and SMS text messages to operators.

For multiple equipment monitoring system, OA-1 On-Line Oil Analyzer continuously keeps monitoring the equipment and reports the oil condition 24 hours/ 7 days, sending the alarm messages to operator by e-mail and SMS text messages to operators.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815 • WhatsApp: 1-913-522-0272

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.