2.1.6 Failure of Low & High Speed Centrifuge

Problem of High Speed Centrifuge in Removing Sludge and Free Water from Oil

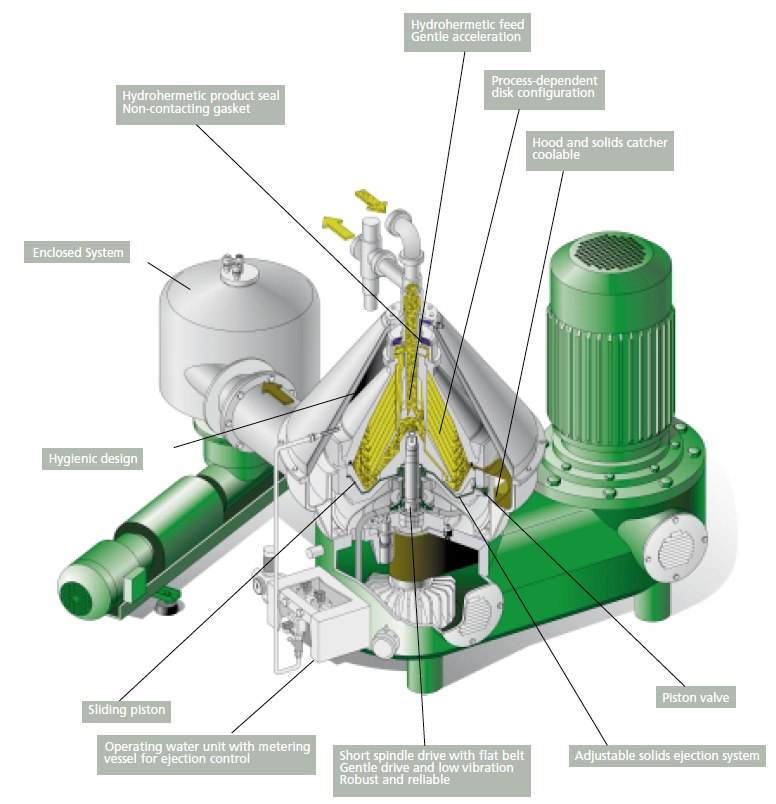

High Speed Centrifuge rotates at 3,000-7,000 rpm so it can be called as High Speed. This high speed can create enough G-Force to separate sludge that has Specific Gravity (SG) higher than oil. Most high speed centrifuge made of Gear Transfer Direct Drive that rotates at 3,500 ppm and enhance more speed through gear transfer to rotate at 5,000-7,000 rpm.

At this high speed there is a bearing to carry load from turning to spin the gear and Disc Shaft to swing the oil in the Centrifuge Housing. Water and sludge will be overflow through the Disc Centrifuge during the rotating. High Speed Centrifuge suppliers are Alfa Laval, Delaval, Samborn, Westfalia, Mitsubishi etc. They are very expensive and require high maintenance to clean or replace Disc Plate and Bearing every 6-8 weeks of run time. They normally take about 7-10 day to repair.

Alfa Laval Centrifuge

Sanborn Centrifuge

5,000-7,000 rpm Rotation is a high turning causes high temperature built up on load bearing. High Speed Centrifuge uses water from outside to cool down the bearing temperature. Bearing Seal usually deteriorates and breakdown once in a while and causes water leaking into the centrifuge housing. Water will be in the lubrication system through bearing seal breakdown.

Westfalia Centrifuge

Hydraulic Oil has Specific Gravity (SG) of 0.84 while Gear Oil is 0.92. Water has SG at 1.00. The Dissolved Soluble can be centrifuged out with the difference between Specific Gravity of oil and water. However the Dissolved Water will not be able to removed by centrifugal force as Dissolved Water is blended into the oil.

Typical hydraulic oil dew point of water is at 7,000 ppm. When Dissolved Water content in the oil is higher than 7,000 ppm, it will become Free Water falling to bottom of oil reservoir. The reverse effect of Free Water in the oil, water will start to penetrate and dissolve into the oil if oil has less than 7,000 ppm of water and become Dissolved Water which is difficult to remove or separate from oil.

Oil contains Demulsifying Agent which is the additive that repels water so it will not easily blend into the oil. When water becomes Dissolved in the oil some of the water will slowly turn into Hydroxyl (OH–) and eventually Hydrogen and Oxygen. Hydrogen in the oil will emulgamate and deplete with other additives to become more oil acidity. All Lewis Acids are composed of Hydrogen. Oil acidity will deteriorate the Seal and O-ring that generates more leaked oil from lubricating system.

Problems of High Speed Centrifuge:

- High Speed Centrifuge can separate Free Water at maximum of 3% or 30,000 ppm at a time. When water content is higher than 3%, it is better to use Decantation as Pre-Treatment for water to settle before using Centrifuge.

- High Speed Centrifuge can only remove water down to about 3,000 ppm. Or maybe lower if oil is heated more than 180°F – 190°F. But this will cause more oxidation and damage the oil.

- High Speed Centrifuge has high maintenance cost. It requires Disc clean up every 1-2 months of operation.

Problem of Low Speed Centrifuge in Removing Sludge and Free Water from Oil

Low Speed Centrifuge or Bowl Centrifuge rotates at 800 – 1,200 rpm and is design for Water Base Fluid such as Machine Coolant only. It is not suitable to use for oil application.

Low Speed Centrifuge uses motor to rotate at 1,750 rpm on fan belt and adjust the rotation to 800 – 1,200 rpm. This speed is not enough to create G-Force to separate Water and Sludge from oil.

The G-Force has to come from 3,000-5,000 rpm rotation so it will have enough centrifugal force to separate water and sludge from oil.

The above information is based on our experiences with users and their comments who wishes the manufacturer can improve their products. Please review with good discretion.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • WhatsApp: 1-913-522-0272 for International call

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.