2.1.9 Failure of Removing Acid with Fuller Earth or Clay Filter

Fuller Earth is made of clay material (Silica) that has the capability to absorb Carbon Pigment in a form of Carbon Black and decolorize the oil or other liquids without the use of harsh chemical treatment. Fullers earth elements are designed to clarify and remove surfactants from hydrocarbon liquids. The primary use of fullers earth is to remove acid in oil reclamation and surfactants in aviation fuels.

Decolorized oil looks clean but this oil is no longer have good lubricating property.

Earlier Fuller Earth or Bentonite Clay has been using to decolorize the vegetable oil and had evolved to decolorize the used engine oil recycling industry 70 years ago. Now it is not appropriate to recycle the used oils as it can not maintain the proper oil chemistry for lubrication.

About 45 years ago EPA (US Environmental Protection Agency) has banned the use of Acid Clay as a hazardous material in large volume disposal in landfill as the acid can escape out entering into the soil and ground water supply.

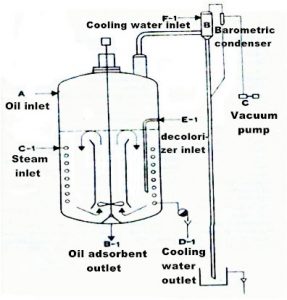

Typical Fuller Earth Filter Machines for Aviation Fuel Filtration

Fuller Earth has been used in commercial cat litter.

Applications:

- Removal of Acids

- Oxidation Products

- Surfactants

- Additives

- Soaps

- Colors

- Soluble contaminants from: Jet Fuel, Mineral Spirits, and Solvents

As the color of the oil changes, sludge is forming in solution with the lubricating oil due to oxidation. This causes a drop in interfacial tension and an decrease in the acid (neutralization) number. Oil additives is a polar compound having similar affinity will also be stripped by Fuller Earth as well.

Fuller Earth creates typical problems in lubricating as described followings:

- Fuller Earth will remove acids in the oil as well as striping oil additives. Most of good additive (Zinc Dithiophosphate ZDDP) and bad additives (Zinc Oxides or Varnish) will be removed by Fuller Earth. When lubricating oil lacks of adequate oil additives, equipment will have less protection from the oil. So the lubricating oil is no longer lubricating the machine. In this Decolorized oil the Oil Film will not form the Thin Film Boundary on metal surface and affects on surface wear on metal during the lubrication.

- Fuller Earth is very small Silica particle having 80% of Particle Size Distribution Curve at 0.5 to 3 micron. When the minute particle dissolves into the oil and makes it hard to filter the small particle out of the oil. Fuller Earth is made of rock material which has very high hardness value, ready to grind metal surface when lubricating the oil.

- The typical 6 micron cartridge paper filter can not remove this minute Fuller Earth particle from oil. If trying to use less than 3 micron filter, the filter will clog immediately due to inadequate surface area to hold extremely high Dirt Holding capacity.

- You may solve acid problem in the oil but you create two more lubricating problems of stripping good oil additives and adding excessive small particles into the oil.

We do not recommend using the Fuller Earth or Clay to remove acid from lubricating oil as it will cause more problems than it’s worth.

The above information is based on our experiences with users and their comments who wishes the manufacturer can improve their products. Please review with good discretion.

Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.