3.12 Oxidation & Water & Particle Count Sensors & Machine Conditioning

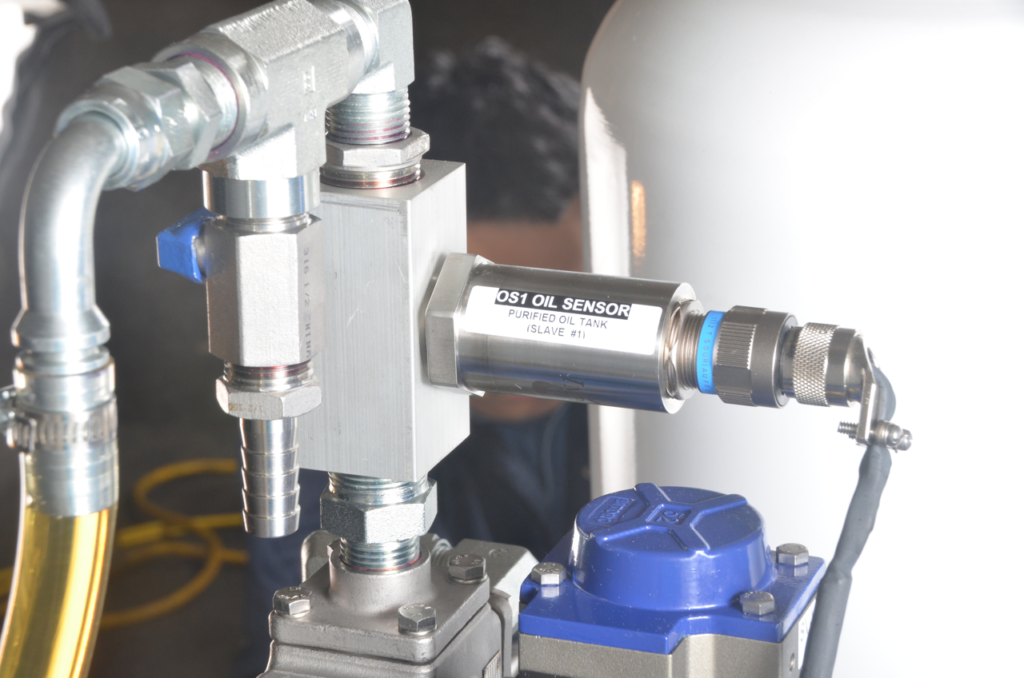

OS1 Oil Sensor – Oil Oxidation and Oil Additive Depletion Detection

OilPure has the opportunity to obtain OS1 Oil Sensor from the US Army that using this type of sensor in their B2 Bomber and F22 Rapter to determine the chemical changes in the oil which this data is related to Oil Oxidation and Additive Depletion in the oil. It is a First Line of Defense to foresee the Real Time oil damages without sending oil samples to lab which is too late and plenty of errors from lab testing as well.

OS1 Oil Sensor measures oil chemical changes by CBM (Condition Based Monitoring).

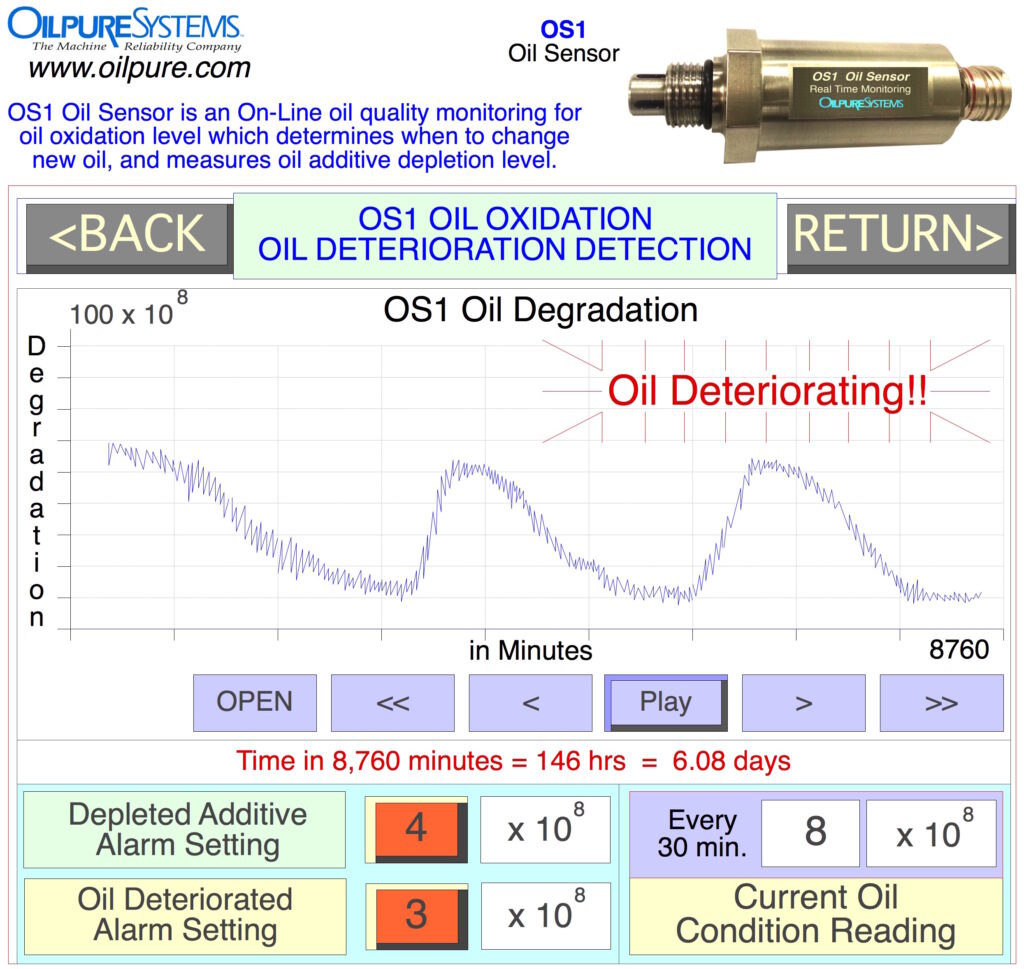

OS1 Oil Sensor reading display on Incremental changes in Oil Oxidation

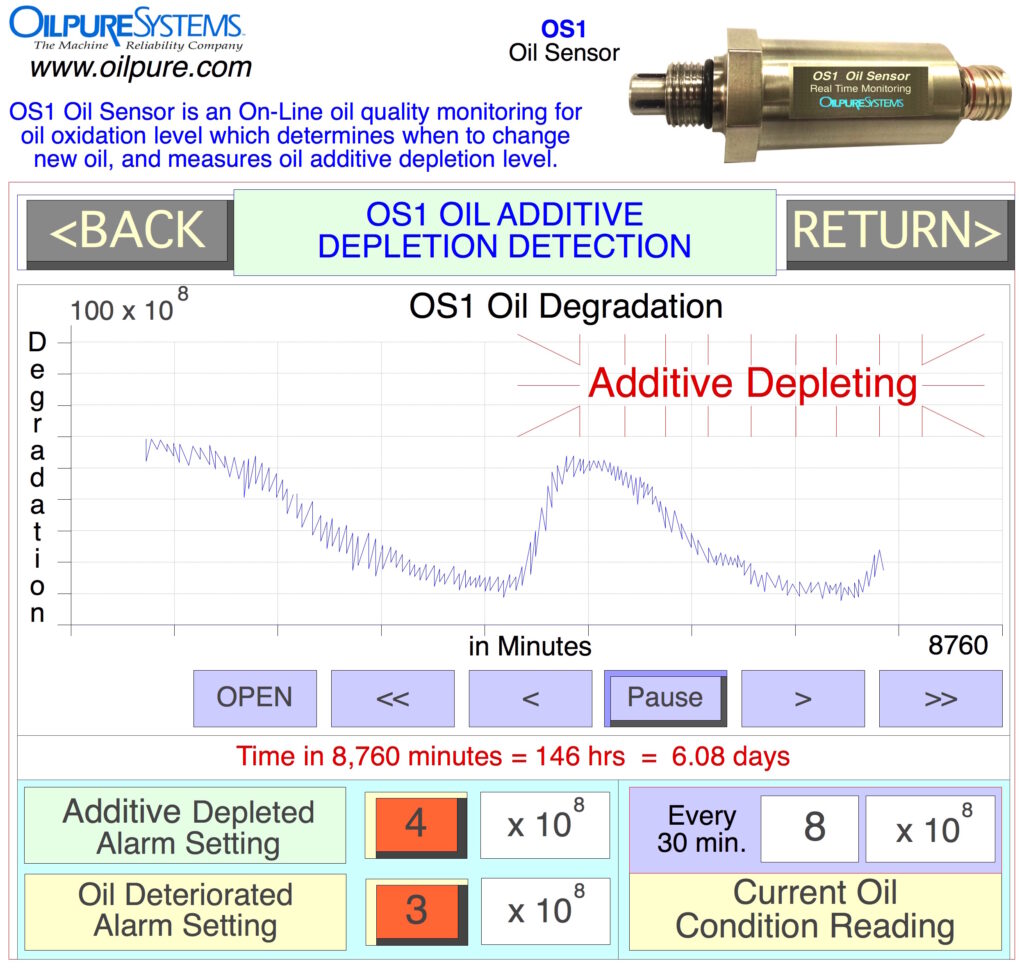

OS1 Oil Sensor reading display on Incremental changes in Oil Additive Depletion

OS1 Oil Sensor can read two different modes for the Changes in Oxidation and the Changes in Additive Depletion. These signal is converted into Analog Signal 4-20 mA, not Conductivity., but OS1 uses the Impedance resistance between Ohmic Resistance and Reactane to determine the changes.

OS1 Oil Sensor Specifications

OS1 Oil Sensor Electrochemical Impedance Spectroscopy

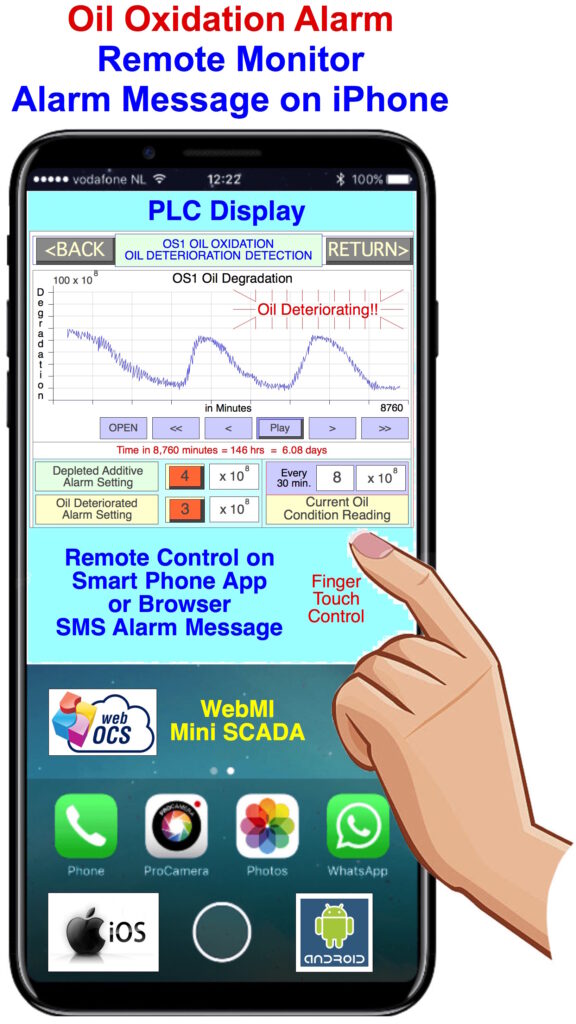

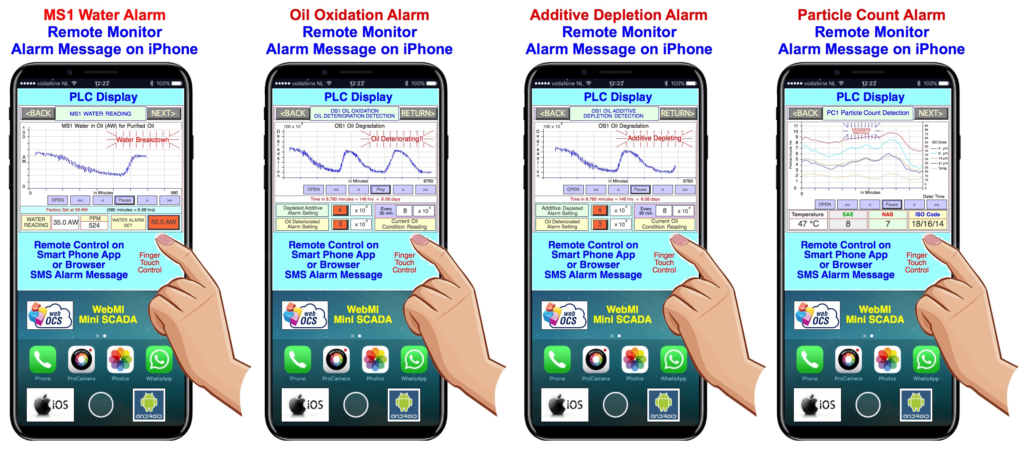

OS1 show the changes in Oxidation curve on the Smart Phone App.

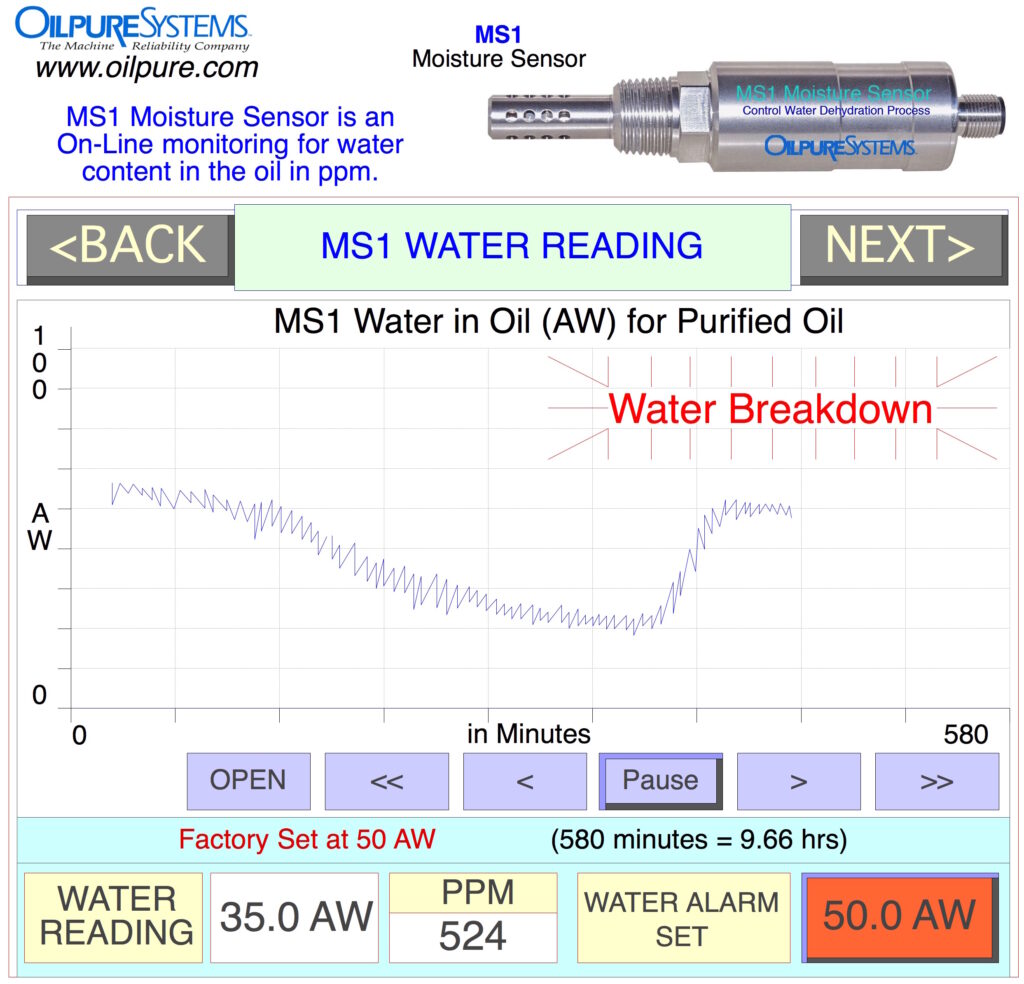

MS1 Moisture Sensor – Detect Water Content in the Oil

MS1 Moisture Sensor reads water content in ppm (parts per million) and % AW (Water Activity) as well as control Vacuum Jet Dehydrating process to make sure that water is always less than the set ppm value in the dehydrator. MS1 is used in all OilPure Vacuum Jet Dehydrator model VJ-50, VJ-100, VJ-150, VJ-300.

MS1 Sensor Port

MS1 Moisture Sensor can read both % AW (Water Activity) and ppm (Parts per million)

Water content data can be kept as Historical Data Login.

MS1 Moisture Sensor can be used in the On-Line Monitoring reading ppm of water from the in-coming oil and still be able to control water dehydration process to assure that water has been removed down to 50-100 ppm before the dehydrated oil is discharged from OilPure Vacuum Jet Dehydrator.

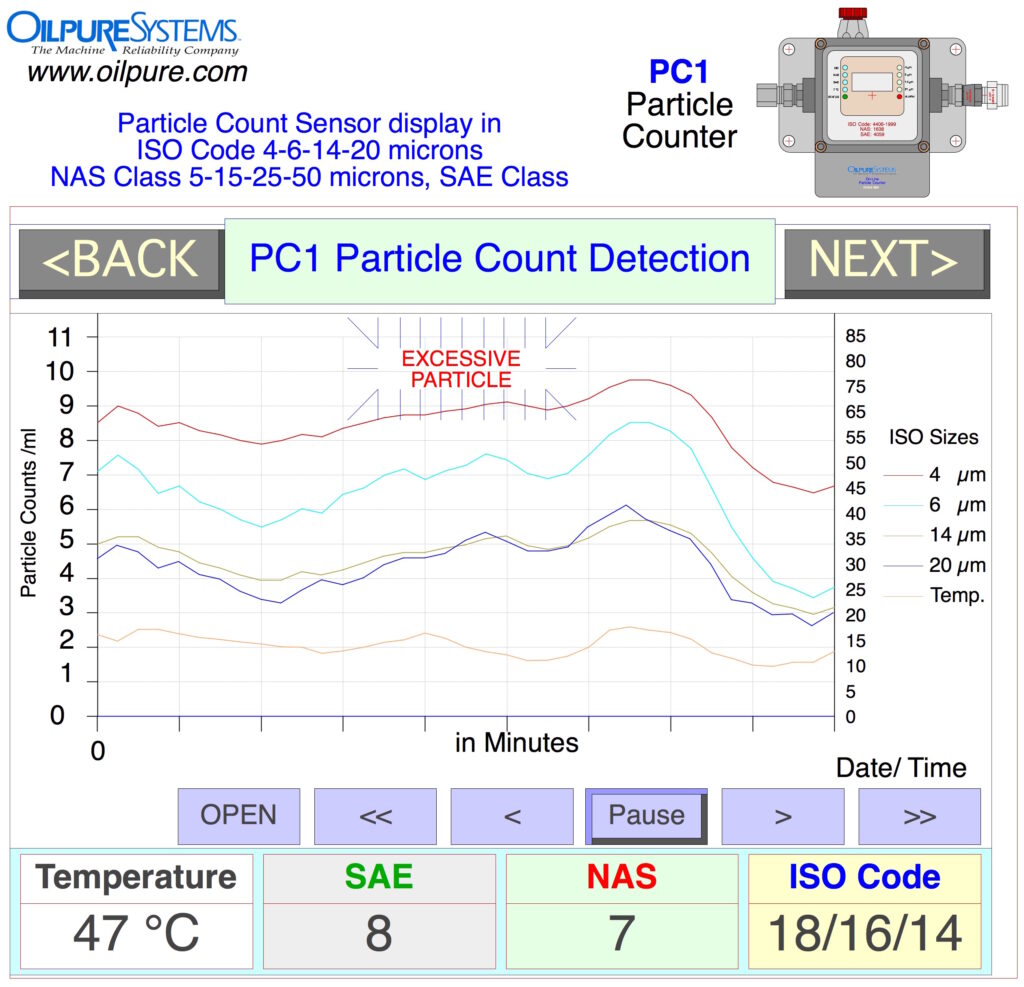

Particle Count – ISO 4406-99

PC1 Particle Count Sensor reads particle in ISO Code, NAS, SAE standards. PC1 is used in the On-Line Oil Monitoring system. PC1 reads Particle in ISO Code for particle sizes of 4, 6, 14, 20 micron display in the curve and number of counts on the display as well as oil temperature data.

User can set the Alarm Value of Particle in the alarm message. The alarm message will send Gmail and SMS Text Message directly to user smart phone as soon as the particle contamination exceeds the limit.

On-Line Particle Count Sensor

PC1 Particle Count Sensor reading display (ISO 4406)

How Particle Count works.

White Light sensor in Particle Counter

Machine Condition Monitoring

Input Expansion of Analog Input Module can be added to OA-1 Oil Analyzer controller to get more Analog Signal from many other sensors that can be used for Machine Conditioning. Data Parameters from these sensors can be set on the Upper and Lower Limits such as Vibration Sensor, Pressure Transmitter, Tachometer , Ultrasonic Level Sensor, J Type Thermocouples etc. So OA-1 is acting as Mini SCADA and performs Monitor Machine Conditioning while equipment is running.

OA-1 On-Line Oil Analyzer with Machine Condition Sensors continuously keeps monitoring the equipment and reports the oil condition 24 hours/ 7 days, sending the alarm messages to operator by e-mail and SMS text messages to operators.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815 • WhatsApp: 1-913-522-0272

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.