3.8 De-Aerator

De-Aeration – v.s.- Entrained Air – v.s.- Air Bubble Removal from Oil

While Vacuum Jet Degasification is capable of removing Dissolved Gases that is compressed in the oil, not visible by the eyes. There are two other gases or air in the oil that also cause foaming problems; Entrained Air and Air Bubble which both of them are visible by eyes. These bigger gases or air come from oil pressure drop in the oil flow causing small gases or air to inflate and become air foam floating in the oil reservoir. This phenomenon occurs under Bernoulli Principle when air is under Cross Sectional Area while Velocity of Gas increases.

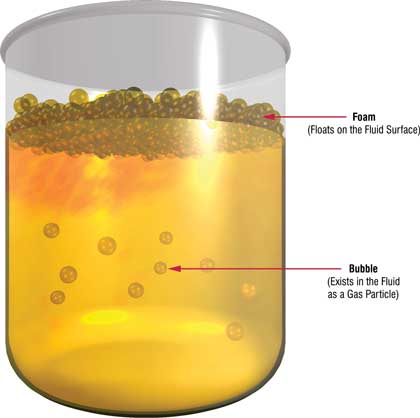

Entrained Air & Air Bubble in Oil Reservoir

Entrained Air is removed.

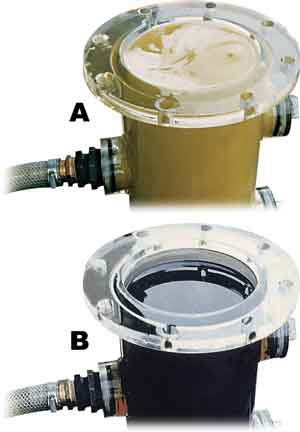

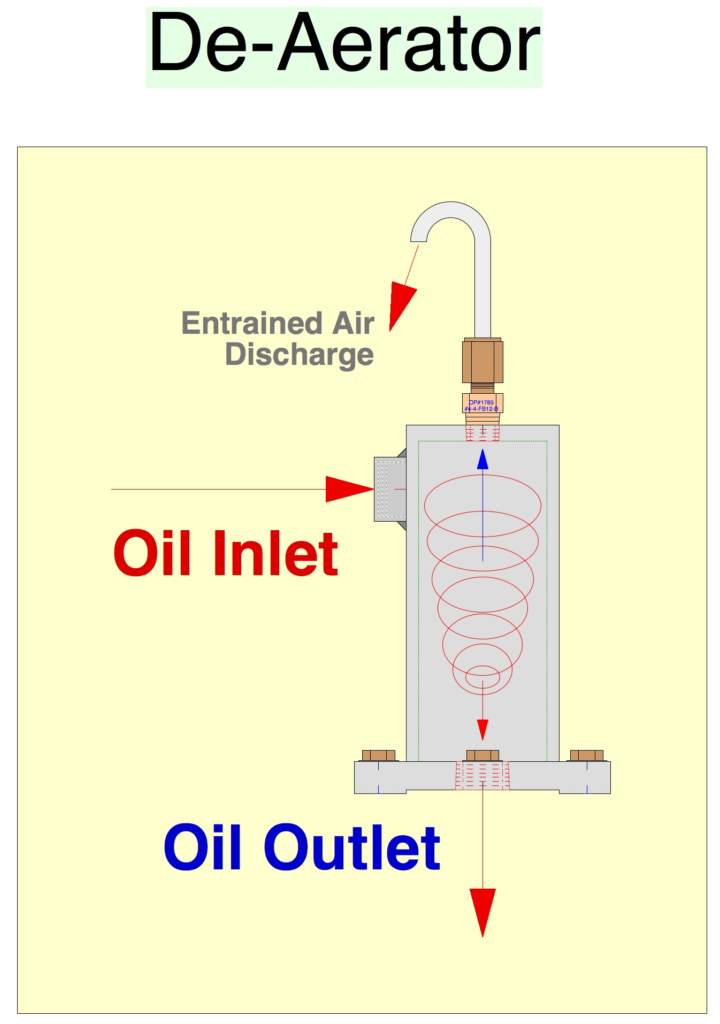

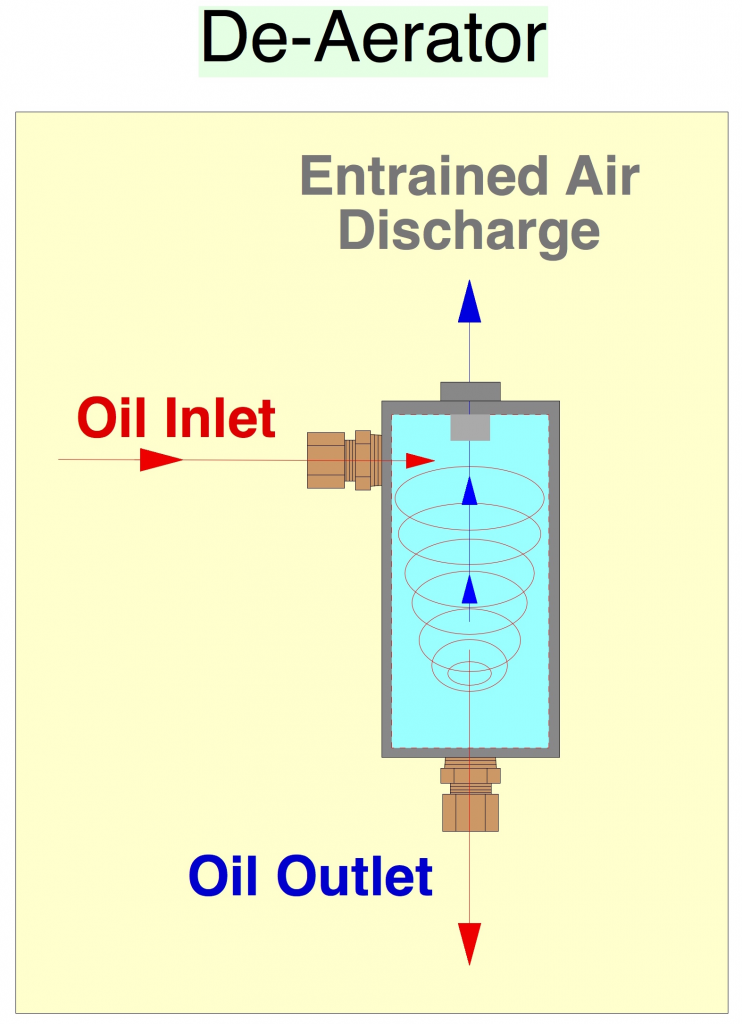

DA-3 OilPure De-Aerator is designed to remove Entrained Air & Air Bubble from oil. These air foaming will breakdown the Oil Film on metal surface during the lubricating process. Air Foaming will reduce Surface Tension and Interfacial Tension (IFT), thus repelling oil film to move away from metal surface. So metal starts to contact other metal surface with no oil film in between. This is just like running the machine with no lubricating oil sticking on surface metals when oil foaming is occurring in the oil.

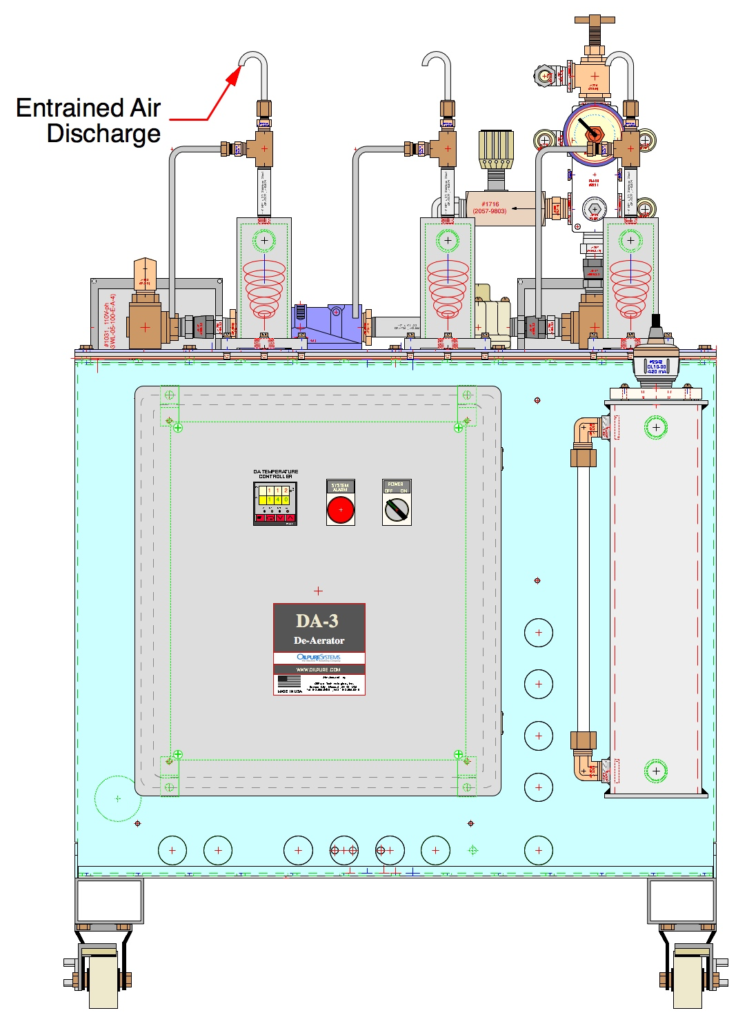

DA-3 De-Aerator Unit

DA-3 De-Aerator Unit from OilPure is good to remove Entrained Air & Air Bubble from oil reservoir size up to 4,000 liters.

- 5.4 GPM oil flow rate with 7 GPM pump capacity.

- Dry weight is about 300 pounds (136 kgs).

- Dimension 28″ W x 41″ L x 39.5″ H.

To solve Dissolved Gases problem is different from solving Entrained Air due to their different Foaming Characteristic. Entrained Air will accumulate into large Air Bubble and become Stable Foam. This is most likely caused by Defective Base Oil and we are not be able to solve this foaming with lubricating technology such as adding Anti Foaming Additive, but replacing with new Base Oil.

The Difference among Dissolved Gases vs Entrained Air vs Air Bubble

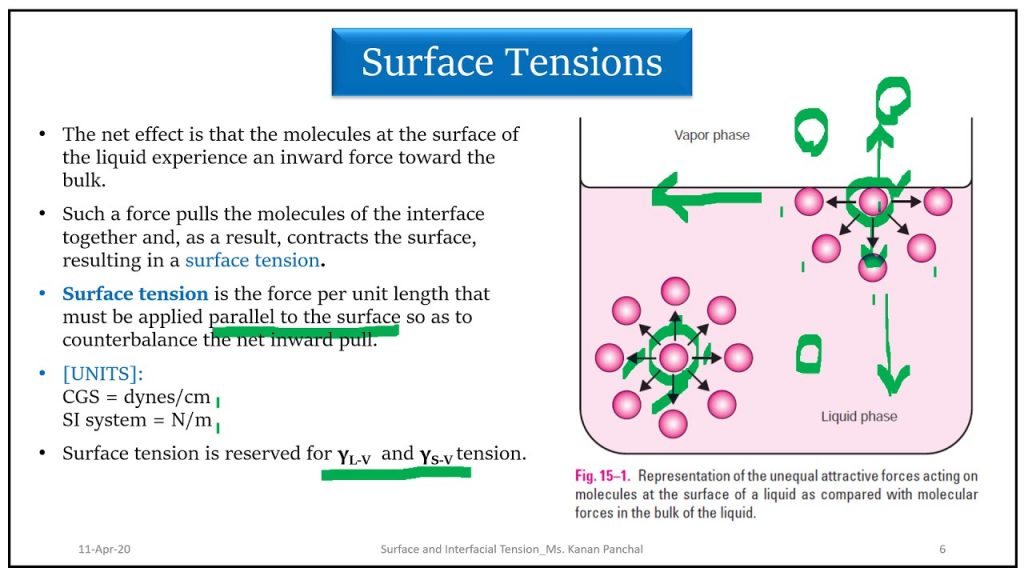

There are two causes of forces that create Air Foaming problem in the oil as described following:

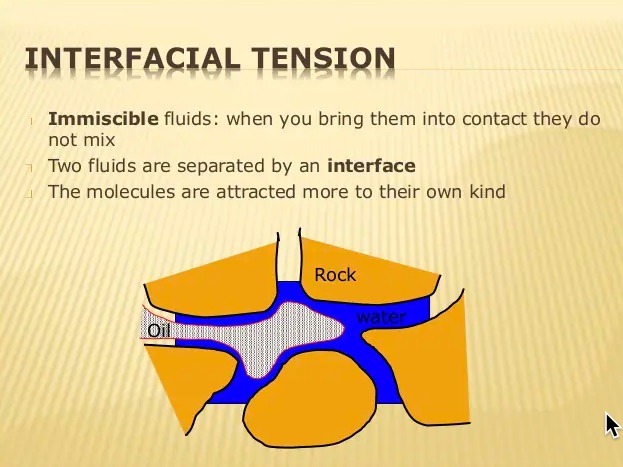

- Surface Tension is molecular force between oil film surface and metal surface that is hold between several oil molecules. This oil film can be described in slippy hand. We can not wipe the oil from our hand. We have to use soap and water to reduce surface tension of oil film and rinse them out with water. Soap is acting as Surfactant to breakdown surface tension between oil film and skin.

- Interfacial Tension (IFT) is molecular force between liquid or oil of how they pull one another so the oil is holding together as liquid while they are flowing. When Interfacial Tension decreases, air foaming start to pull in between oil molecules and becomes Entrained Air or Air Bubble depending on the sizes.

- Dissolved Gases

Dissolved Gases is very small, soluble of air foaming dissolved and emulsified in the oil, not visible by eyes. The gases in positive displacement pump was mostly compressed from suction side and decompressed from the discharge side of the pump with oil pressure and heat in the oil. Dissolved gases usually have little effect on lubricating process when they are dissolved in the oil. Dissolved Gases can be compressed in small foam or decompressed into larger foam during lubricating process. Larger foam definitely can cause Cavitation as it will reduce surface tension from oil film and metal surface, thus affecting excessive wear on components.

Dissolved Gases

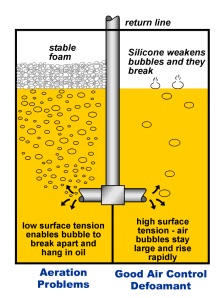

Anti Foaming Additive is normally used in the oil to control the Surface Tension and Interfacial Tension that prevents air foaming not to easily form in the oil. This Anti Foaming Additive is made of Silicone that is very sensitive to oil oxidation. It is the first one to go for additive depletion occurred from oil oxidation.

Excessive Stable Foam is caused by oil contamination such as Water, Oxidation or Oil Acidity that reduces Surface Tension in the oil.

Dissolved Gases can be removed from oil by Vacuum Jet Degasification.

2. Entrained Air

Entrained Air is a larger air foaming, mostly inflate from Dissolved Air or Gases when oil is agitating or turbulent flow. Large air foam usually starts from the bottom and rise to the top becoming the Tendency Foam within 5 minutes. This is considered as normal.

Entrained Air caused by oil contamination such as Water and Oxidation or Higher Oil Acidity that reduce both Surface Tension and Interfacial Tension.

Entrained Air can be removed by DA-3 De-Aerator from OilPure. Anti Foaming Additive that is made of Silicone, can be refortified into the clean oil only. This will help to control a better Tendency Foam in the oil. However, this can be done only when oil is free of water and oxidation.

If Tendency Foam does not disappear soon, it will keep forming the Stable Foam which causes more damages to the machine.

3. Air Bubble

Air Bubble is normally a larger foam that is inflated from Dissolved or Entrained Air. It starts after Anti Foaming Additive has been depleted and oil has been agitated for a long period of time. This Air Bubble will not easily disappear and can become the Stable Foam that Air Foaming can explode from the manhole tank of oil reservoir.

This Air Bubble can be removed by DA-3 De-Aerator from OilPure with the help of Anti Foaming Additive refortification.

Except when Air Bubble becomes Stable Foam that has a root cause from Defective Base Oil from refinery plant. DA-3 De-Aerator can only alleviate the foaming situation with Anti Foaming Refortification, but will not solve Air Bubble in Stable Foam problem.

- There are 6 causes of Air Foaming in the Oil as listed followings:

- Oil Contamination such as Dissolved Water and Oil Oxidation occurring during the overheated oil for a long period of time.

- Depleted Anti Foaming Additive can affect poor Surface Tension and causes excessive Air Foaming.

- Excessive Surfactant infiltrates in the oil reservoir. This can cause excessive foam.

- Poor Machine Design that has plenty of dead zone from 90° angle pipe corner. Fluid Flow can cause excessive heat within the corner of pipe. This causes pump cavitation in hydraulic system. It is an poor OEM design problem.

- Defective Base Oil from refinery that has periodical poor quality control problem, can cause an unresolved foaming problem. Defective Base Oil has incompatible with additives and unable to become homogeneous showing a white gluey color in the oil. Most oil blenders will add more Dispersant Additive to solve this homogeneous problem. But it is only masking the problem.

- Defective Base Oil from refinery that has long term poor quality control problem. The whole production lot of base oil has been defective. By over dosing Dispersant Additive will have the side effect and more air become the Air Release Issue that creates Large Stable Air Foam. This Large Stable Foam does not act like normal air foaming but become a chuck of liquid foaming that expands and explodes out of oil reservoir from the top manhole.

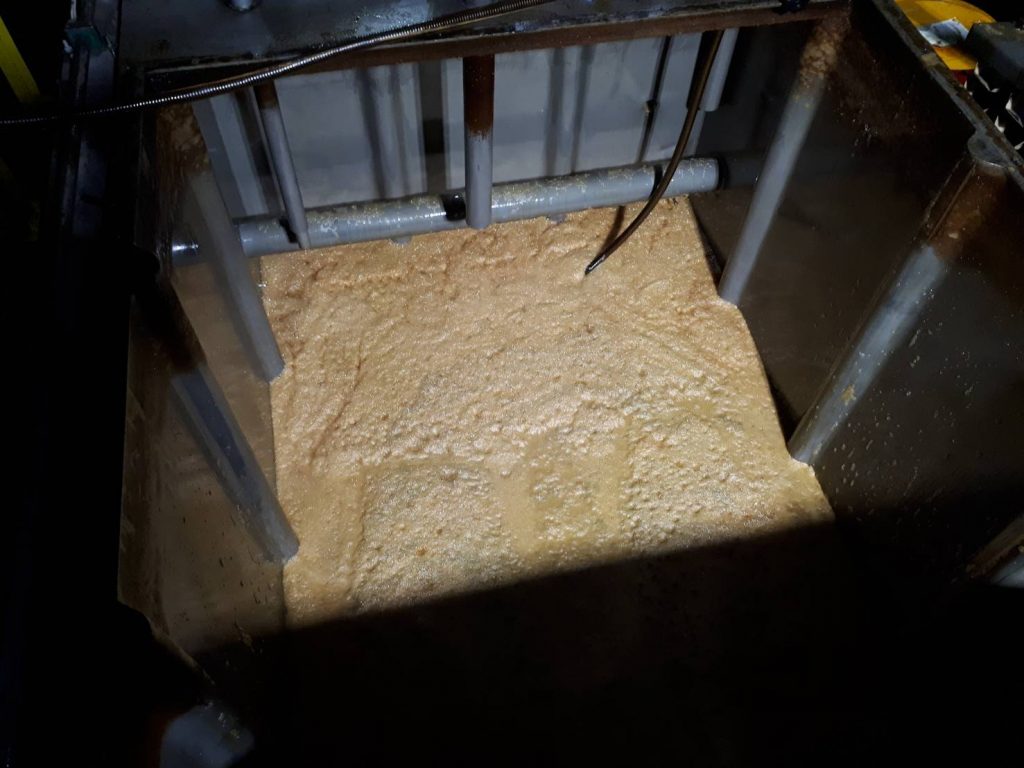

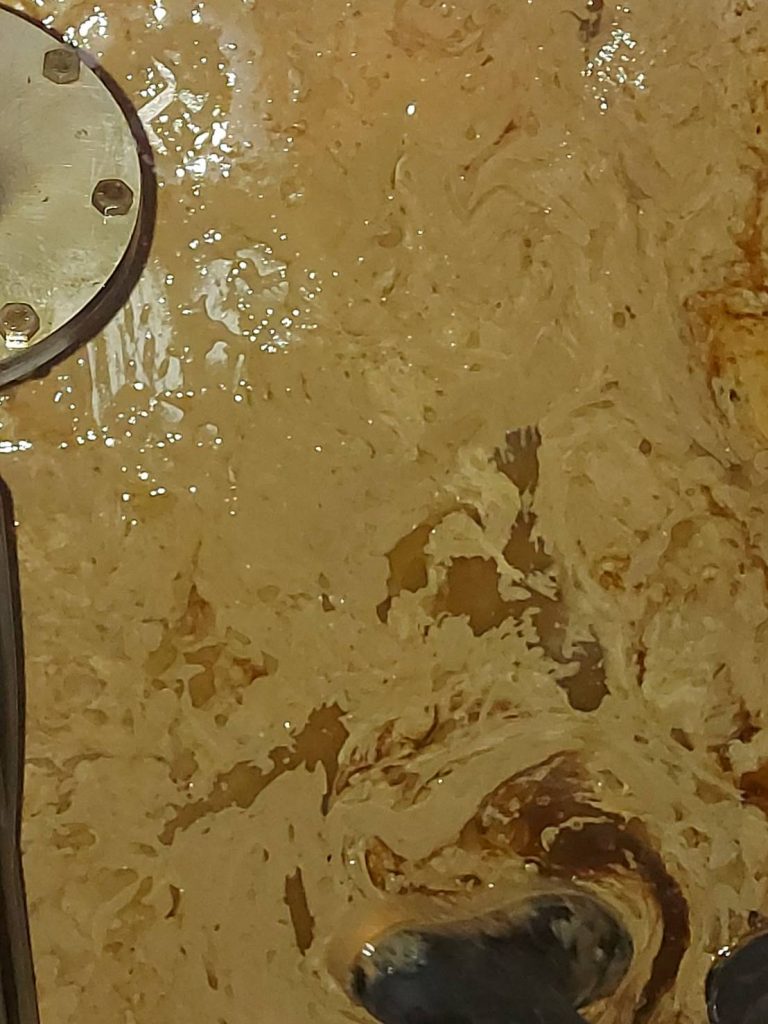

Large Abnormal Air Bubble Foam in the tank.

Air Bubble Foam explodes out of oil reservoir.

Air Bubble Foam still stays at the bottom of oil reservoir after oil was drained out.

Air Bubble Foam expends all over oil reservoir.

Air Bubble Foam at the Manhole tank.

The video shows how bad the Air Bubble Foam flowing out of oil reservoir as Liquid Foam like a milky cream. This Air Bubble Foam does not dissipate easily and become Stable Foam. This normally caused from Defective Base Oil from refinery. There is no solution to this problem but replace with new oil from different source.

Free Water at the bottom of oil reservoir is a major cause of Air Foaming in the oil. Air foam will develop into all 3 Air Foaming: Air Bubble, Entrained Air, Dissolved Gases

Free Water at bottom of oil reservoir is the source of Bacteria & Micro Organism that their growth will generate H2S Hydrogen Sulfide as well as system corrosion in the oil.

When Free Water has been collected at bottom of oil reservoir for a long period of time, oil at the bottom will appear like “Yogurt Oil”. This Water like Yogurt Oil will make it impossible for conventional Vacuum Distillation to remove from oil. This Water Like Yogurt Oil must be pulled out from oil reservoir into DT-100 Free Water Separator prior to any water dehydration of this oil.

Adding Anti Foaming and Dispersant Additives may not solve this Liquid Foam problem. It could backfire the foaming problem to increase surface area so the air foam will adhere together and become a Liquid Foam as illustrated on the above photos and video.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.