Dissolved Water & Free Water

Water Problems in Lubricating Oil

Nature of Water

- By Nature there are two types of water in lubricating oil which both them have totally different in its Physical and Chemistry Properties. So it will take two different separating processes to remove each water from the oil. It has been a misunderstanding that Vacuum Dehydration can remove both Free Water and Dissolved at the same time.

- These two type of Water are:

- Free Water is water droplet that can be visible by eyes. Free Water can be vapor droplet floating out in the air and normally will not easily dissolve with other liquids. Free Water also settles to the bottom of oil reservoir and normally get into oil reservoir through leaking of Oil Cooler, Heat Exchanger. By nature Free Water normally doesn’t want to mix or dissolve in the oil. When water is mixed in the oil, it mixes so well as Dissolved Water form and will not be easy to remove this Dissolved Water from oil. Free Water always tries to settle to the bottom as Free Water is heavier than oil. We can use Gravity or Centrifugal Force to separate Free Water from oil.

- Dissolved Water is the water emulsion and dissolved in the oil. Dissolved Water is an excellent emulsifying with oil and becomes water and oil emulsion. Once Free Water becomes Dissolved Water in the oil, it becomes Homogeneous and emulsified that Gravity or Centrifugal Force will not be able to separate them from oil.

- Water Nature in oil can be described as follows:

- Water moves from high level to low level. Free Water has Specific Gravity (SG) = 1.00 while hydraulic oil has Specific Gravity (SG) = 0.84 and Gear oil SG = 0.92. Free Water will always settle to the bottom of oil reservoir with time.

- Free Water is always on the slow move all the time at bottom of the oil reservoir. Most people mistakenly think that Free Water will sit idle and settle at the bottom of oil reservoir. Especially when oil in the reservoir has higher than 50 °C. Both Free Water and Dissolved Water will float up and down continuously when oil is heated as temperature keeps changing their Specific Gravity up and down due to oil viscosity change from heat. During this up and down movement there is always exchange between Free Water turns into Dissolved back and forth (condensation) in the heating oil. As oil becomes emulsified from Free Water, oil shows the milky look for more Dissolved Water in the oil.

- Water normally transmit from Wet Condition to Dry Condition in the form of Water Condensation such Humidity in the air moves from wet to dry weather. The dissolved Water in the air will build up and become Free Water to rain out in the air. Dissolved Water will transmit to drier area and accumulates into Free Water until it reaches Water Saturated Point or Dew Point. Dissolved Water will become Free Water after this Water Saturated Point or Dew Point. At this Dew Point, water will stop transmitting. The transmitting between Free Water to Dissolved Water through Condensation will increase with different temperature in oil (Delta T), especially when oil is a medium between water.

- Water Transmitting or condensation among both Free Water and Dissolved Water is controlled and designated by Water Saturated Point or Dew Point between media. This works the same way as water in the air reaches its Dew Point when Relative Humidity is at 100%. Water in oil is the same. Water Saturated Point or Dew Point in typical hydraulic oil is about 7,000 ppm.

- When Free Water leaks into lubricating system and oil in the reservoir has only 500 ppm of water, Free Water will transmit in the drier oil in Dissolved Water form until the water content reaches its Dew Point at 7,000 ppm. Then, Free Water will stop transmitting into the oil as Dissolved Water and will settle to bottom of oil reservoir. So when user pulls the oil sample and found more than 2,000-3,000 ppm of water, this number described as there is water leakage from Oil Cooler or Heat Exchanger in the lubricating System. Most likely you will find more Free Water settled at bottom of oil reservoir as well.

- When Relative Humidity of the plant site is at 70% or higher, moisture in the air will try to transmit into the oil through condensation by air and oil contact either by actuator or air breather in oil reservoir. Dissolved Water in the oil from 500 ppm will slowly increase to 700, to 1,000 to 1,500 ppm and will eventually stop at about 2,000 ppm. So when user pulls the oil sample and found 1,200-1,800 ppm of water, this number described as there is water condensation coming into the oil, not water breakdown from Heat Exchanger. Water Condensation rate will increase when oil temperature at 65°C – 75 °C and ambient temperature is at 30 °C with 70% Relative Humidity due to different between oil and air temperature (Delta T).

- Both Free Water and Dissolved Water is always on the move toward each other in oil by Condensation, transmitting between wet and dry area and gravity from high level to low level. The movement of water is always stimulated by increasing oil temperature.

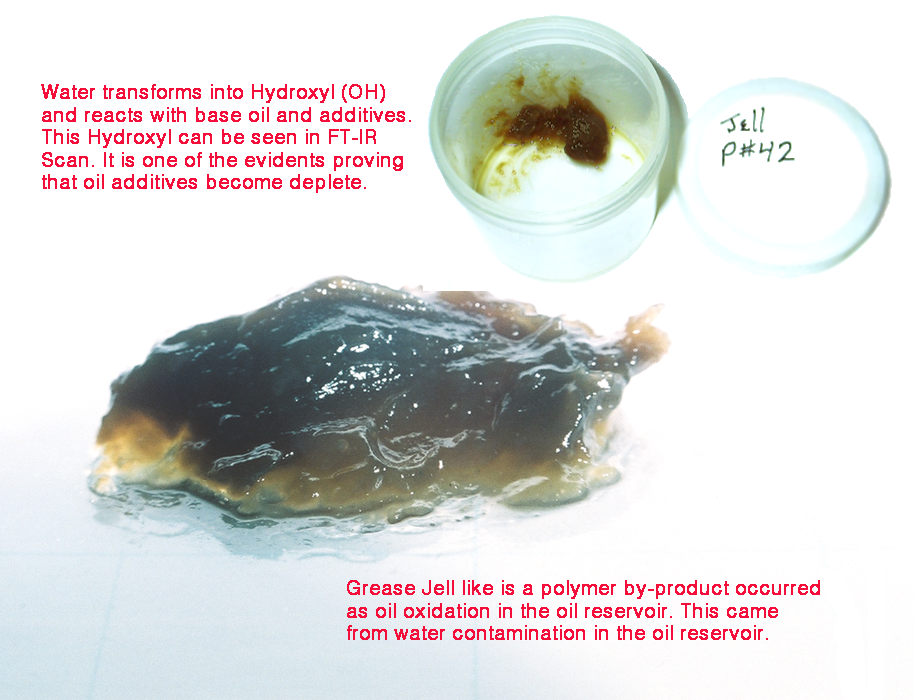

- When large amount of Dissolved Water such as 3,000 ppm is in the oil at 65 °C or higher oil temperature for more than 2-4 weeks, this Dissolved Water can easily transform into Hydroxyl (OH–). Karl Fisher Water Analyzer may show less water content in the oil or water becomes less appearance. Water did not disappear but becomes Hydroxyl (OH–) or H2 Hydrogen and O2 Oxygen in the oil. These H2 Hydrogen and O2 Oxygen will create more oil problems causing rapid changes in Oil Oxidation, Oil Additive Depletion and several internal component corrosion afterward.

Oil Oxidation Caused by Hydroxyl (OH–) from Previous Water Breakdown in the Lubricating System

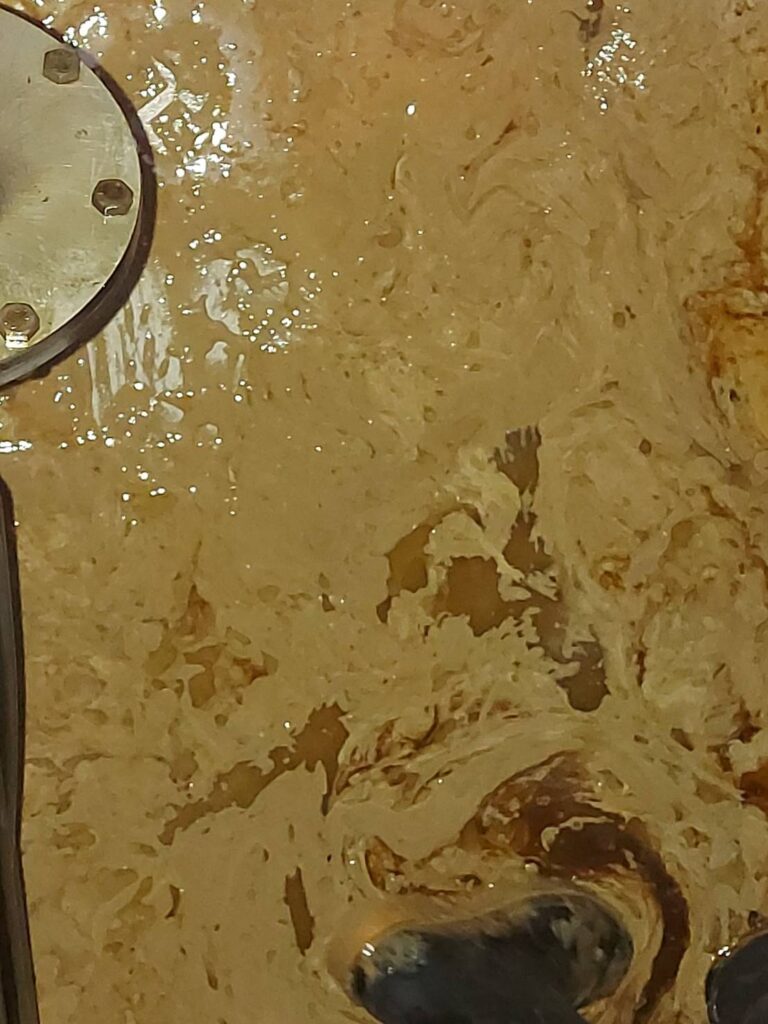

Oil Oxidation can occur from Hydroxyl (OH–) causing from previous water breakdown into the lubricating system. You can look at the Oxidation Paste that stick inside bottom of the oil reservoir as looks like the below photo. This describes the oil oxidation that came from the previous water breakdown.

The above oil oxidation by product photo came from Husky Injection molder having water breakdown several time in the US manufacturing plant.

This oil oxidation occurs when water breakdown through Heat Exchanger or slow water leaking in the system and the water problem got noticed. New oil replaces the old oil from the reservoir. However, there is about 20% of the old oil left in the pipe line, cylinder, valve, pump that can not be drained out. So the new oil replacement is adding 80% of new oil and mixes with 20% of old oil. So the new oil mixture still have plenty of water in the new oil replacement in the oil reservoir.

Free Water and Slurry, Yogurt Like Oil at the bottom of oil reservoir is a major cause of Air Foaming in the oil. Air foam will develop into all 3 Air Foaming: Air Bubble, Entrained Air, Dissolved Gases

Free Water at bottom of oil reservoir is the source of Bacteria & Micro Organism that their growth will generate H2S Hydrogen Sulfide as well as system corrosion in the oil.

New oil has plenty of Water Demulsifier Agent Additive that can is still able of depressing Water and hold them into Hydroxyl (OH–) that will transform into H2 Hydrogen and O2 Oxygen. The milky look of new oil replacement will slowly disappear from oil reservoir in the next 4-5 days after new oil replacement. This leads to believe that water in the oil is evaporated from the system. Water did not disappear but transform into H2 Hydrogen and O2 Oxygen.

H2 Hydrogen can easily react with Hydrocarbon Base Oil and its Additives to become Carboxylic Acid, thus increases Oil Acidity. All acid molecule always has Hydrogen inside. Oil Oxidation by products that came from Hydroxyl (OH–) will look like Gel as shown on the above photo.

These oil oxidation by product photos came from Paper Mill plant in Thailand.

After oil acidity increase, acidity will react with Elastomer of rubber O-RIng and Gasket causing Elastomer deterioration and getting hard and brittle. This will definitely affect the seal and gasket deterioration causing leaking oil from the reservoir within the next 6-9 months. User will notice more of leaked oil problems become omnipresence.

From hydroxyl (OH–) there will be plenty of O2 Oxygen in the oil. This excessive O2 Oxygen will react with Iron to become Iron Oxides and forms Rusting Internal Corrosion in the oil. Oxygen is also acting as Oxidation Catalyst when oil is heated.

Therefore, new oil replacement does not end as solution. It is only beginning of many equipment problems afterward if user doesn’t know how to provide proper Oil Contamination Control.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.