Oil Additives

What is Oil Additives?

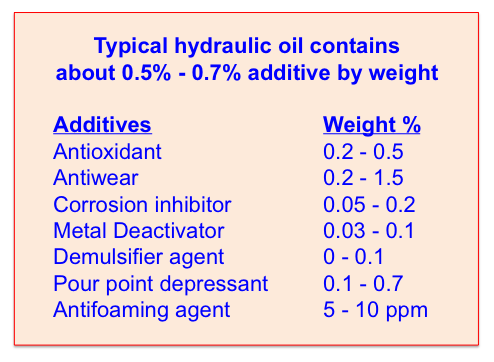

Oil Additives is made of Petroleum Chemicals or Oleic Chemicals, Ester base fabricating from Fatty Acid in vegetable oil and Petroleum Products. Base oil alone is not good for lubrication. Without oil additives base oil is no use for lubrication.

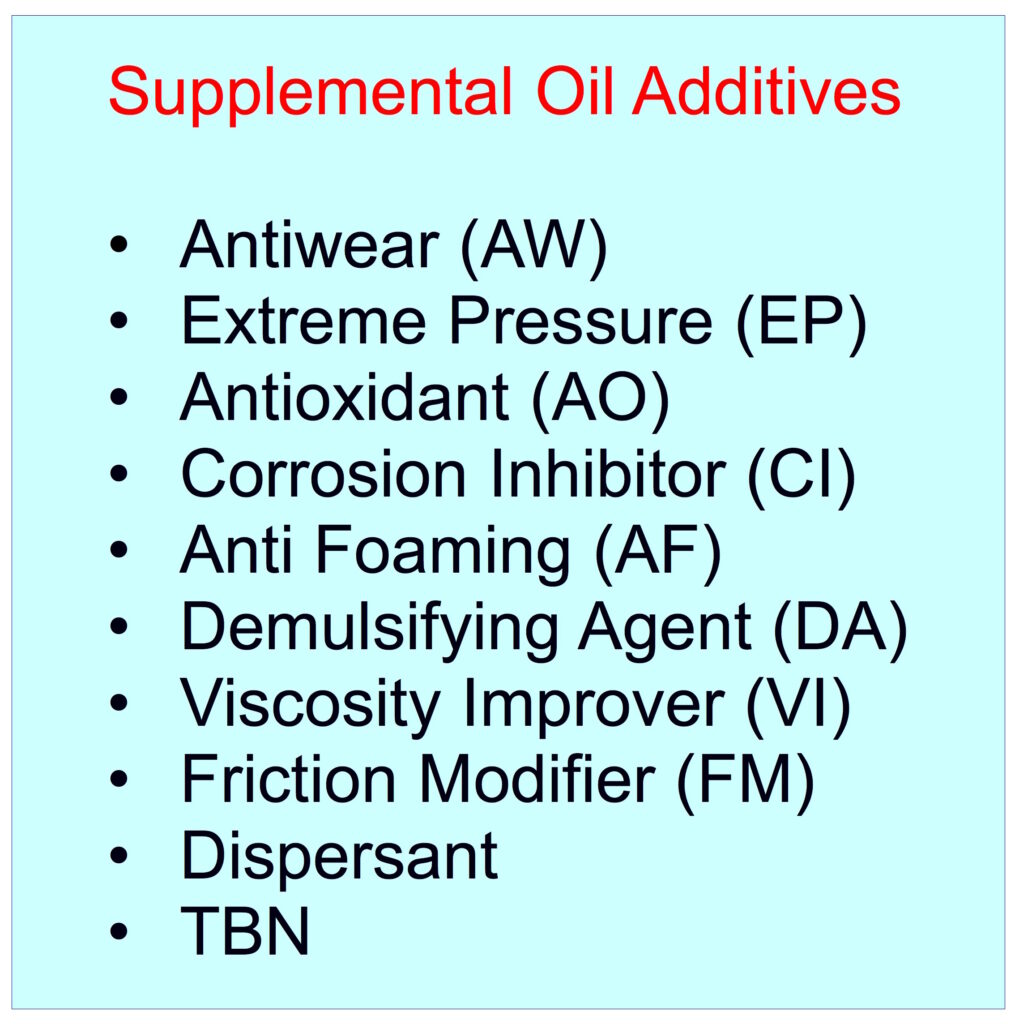

- Industrial lubrication is easily made of Oil Additive Packages that were manufactured by Chemical companies. Different type of Oil Additive Packages are made of different viscosity grade base oil. Oil Additive Packages were blended with different Additive Components within the requested formula from the oil company. Today industrial lubrication becomes a mature market. There are many competitions come to the market and ending up compete in lower cost. There is not much of R&D and new development in making lubrication 30 years ago. Most of lubrication technology have been discovered and in use today. Market situation drives oil companies as follows:

- Most lubrication companies do not have manufacturing facility for their base oil. They all purchase base oil from Independence Oil Refinery plants.

- Most lubrication companies do not manufacture their own Oil Additives. All of them purchase Oil Additive Packages from Chemical companies.

- Most lubrication companies do not have their own oil blending facility. All of them subcontract Independence Oil Blending company or Oil Jobber to blend the oil under their name.

- Big oil lubricating oil companies spent enormous amount of advertising to create the Brand Name Recognition to lead oil user to believe in their high quality performance lubrication. The brand name lubrication demands higher price from customer believe and makes plenty of profits. Today customer becomes more educated and causing market disruption.

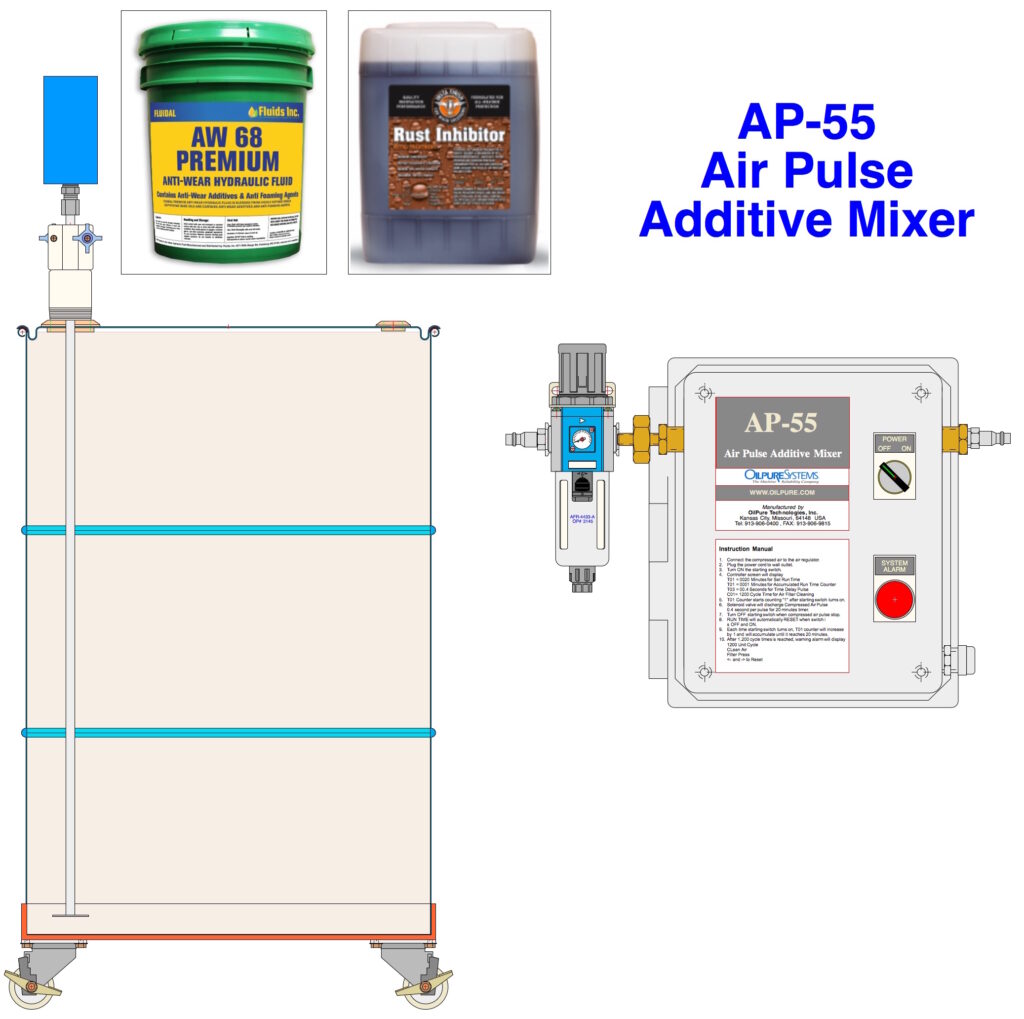

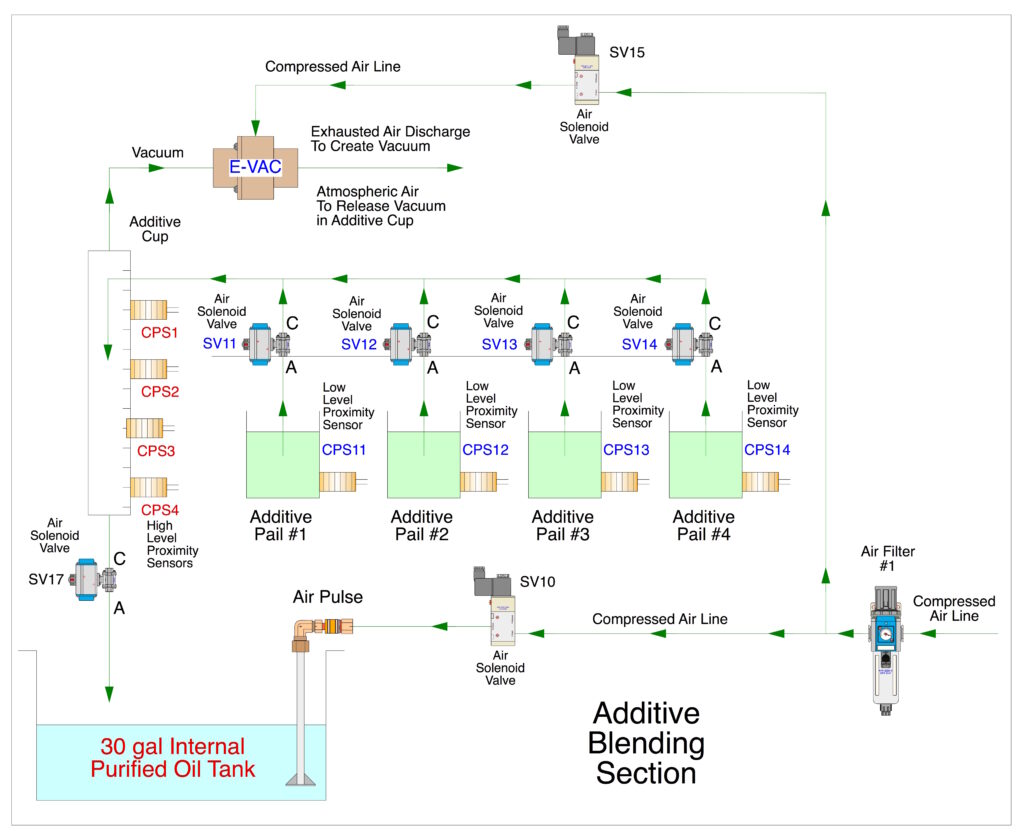

AP-55 is OilPure additive mixer to blend Additives and Base Oil using compressed air.

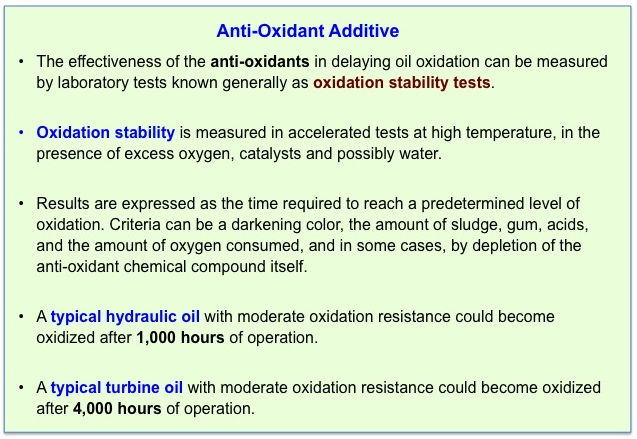

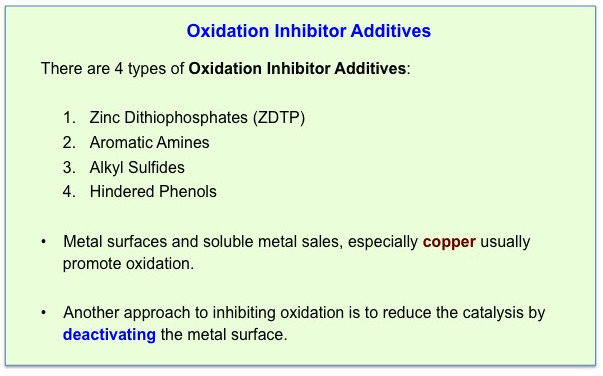

Anti Oxidant Additive is controlling Free Radicals not to react with Oxygen (Catalyst) during lubricating process. Most oxygen in the oil is in dissolved gas form and can easily oxidizes into Peroxides and oxides which become oil oxidation and forms Oxidation by products such as Varnish etc. in the oil.

- In general there are two type of Oil Oxidation:

- High Thermal Oxidation looks like hard brownish color, dried chocolate like sticking on part surface. They are very hard material but very Brittle.

- Low Thermal Oil Oxidation looks like Greasy soft material stick on part surface.

OilPure MB-50 has additive blending capability after oil is purified.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.