3 Product Lines

- OilPure Technologies, Inc. is the manufacturer of oil purifier equipment, located in Kansas City, Missouri USA. OilPure development involves in 3 following technologies as follows:

- Oil Purifier is the hardware units.

- PurePack is OilPure proprietary chemical filter, specifically removes Total Oil Contamination from oil, thus extending the life of lubricating oil for several decades.

- Operating Softwares control OilPure equipment for automation, IIOT4.0 and Mini SCADA.

OilPure Product Line

- Sludge & Heavy Sludge Separator

- Turbine Jet Centrifuge – High Speed – TC-8 & TC-4 for Cutting Oil with excessive metal fines & Swarf, Quenching Oil with excessive Carbon Particulate, Cold Header Machine having 10% of Sludge.

- Small Centrifuge – TC-4 @15 GPM, 4,000-6,000 rpm speed, removes 10 pounds of sludge from oil per day. Good for oil reservoir size 50-100 gallons.

- Large Centrifuge – TC-8 @30 GPM, 4,000-6,000 rpm speed, remove 20 pounds of sludge from oil per day. Good for oil reservoir size 100-200 gallons.

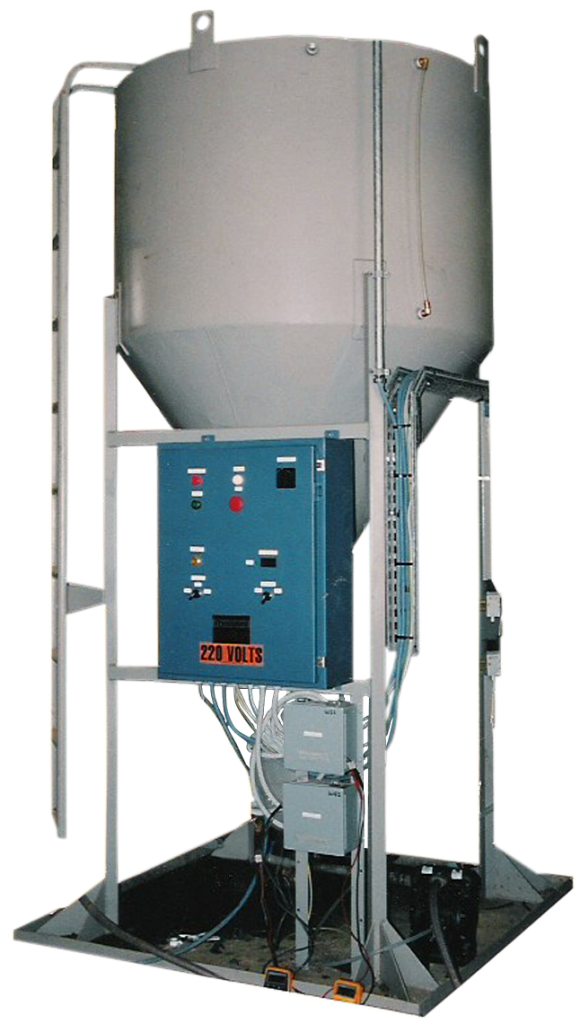

- Gravity Separator – Fluid Force Theory – GT-400 utilizes sludge weight to speed up the gravity separation in 24-48 hours while a normal gravity tank separation will take 1-2 weeks. GT-400 is good for separating 10%-70% of sludge in the oil. GT-400 size 400 gallons, cone bottom tank with automatic drain.

- Turbine Jet Centrifuge – High Speed – TC-8 & TC-4 for Cutting Oil with excessive metal fines & Swarf, Quenching Oil with excessive Carbon Particulate, Cold Header Machine having 10% of Sludge.

- Free Water Separator

- Free Water Separator – DT-100 utilizes Dynamic Separation Technology to split Free Water from oil while oil is flowing through a Coalescing Media. Water will force to split down to the bottom while oil rises on top. WS1 Water Sensor will detect Free Water Layer Interface and drain water from DT-100 automatically. Free water separation & removal, automatic drain 20 gallons of water per hour.

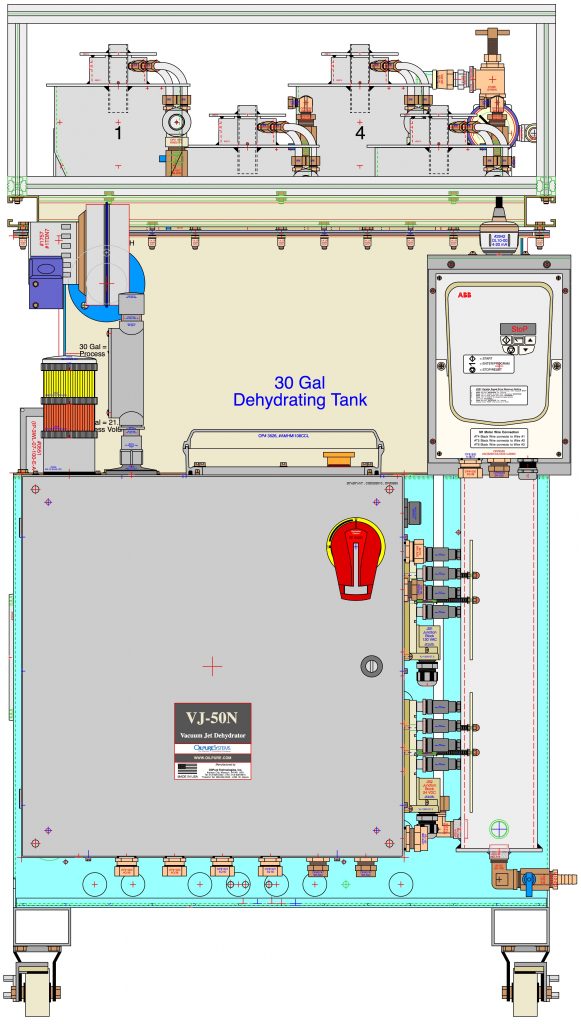

- Vacuum Jet Dehydration – Dissolved Water Removal

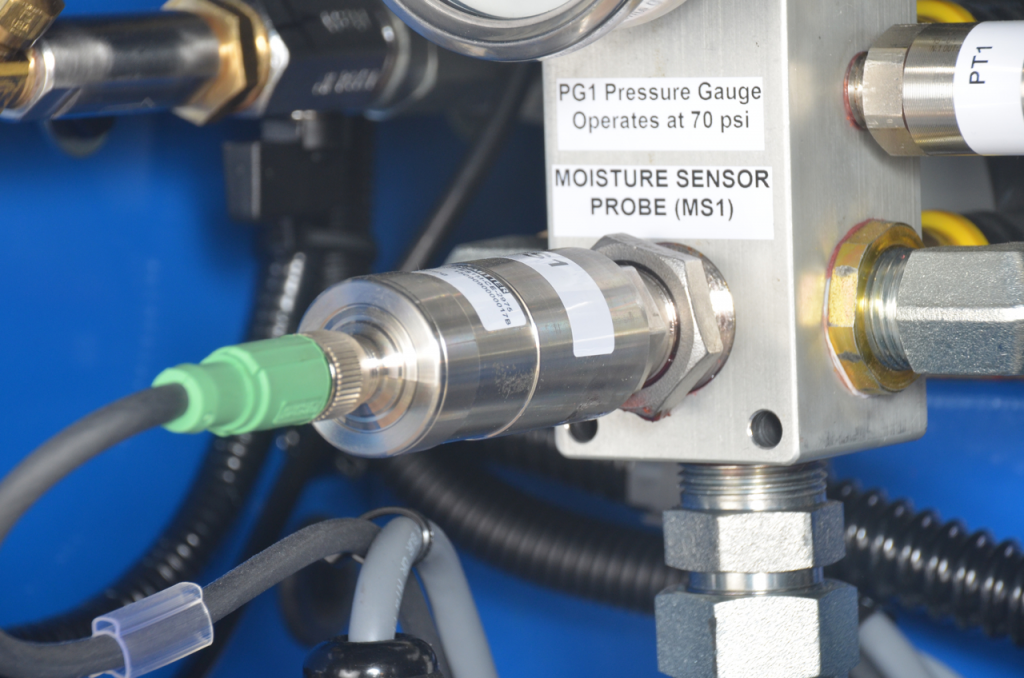

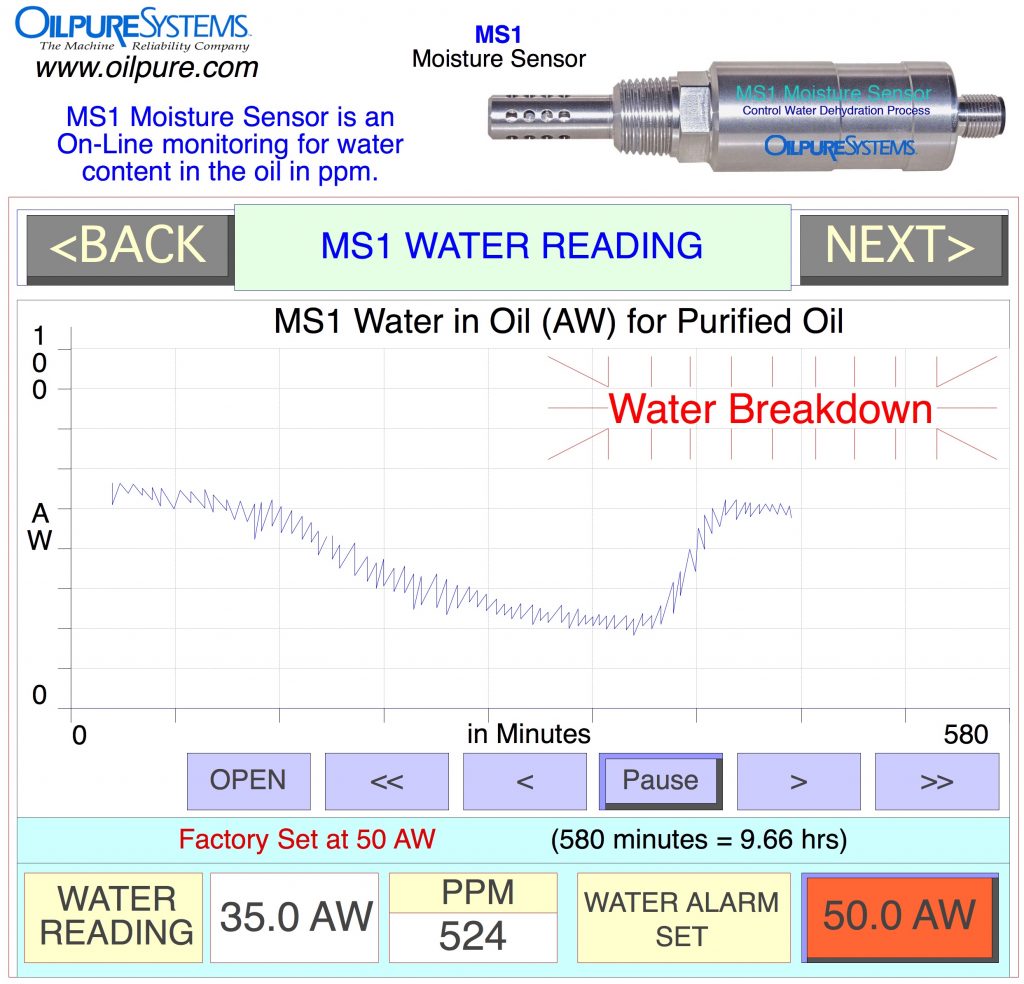

- Vacuum Jet Dehydration – VJ-25, VJ-50, VJ-100, VJ-150, VJ-300, VJ-300DT utilizes Atmospheric Air to absorb dissolved water of 2,000 (0.2%) – 50,000 ppm (5%) down to 50 ppm (0.005%) in the oil. MS1 Moisture Sensor is used to control water dehydration and reads water content in ppm and % AW (Water Activity) to assure that the discharged dry oil has water less than 50-100 ppm from Vacuum Jet Dehydrator.

- VJ-25 Machine. Good for oil reservoir size 100 – 150 gallons with water content of 5,000 – 10,000 ppm

- VJ-50 = VJ-50 + FC-1 Machine. Good for oil reservoir size 400 – 500 gallons with water content of 5,000 – 30,000 ppm

- VJ-100 = VJ-100 + FC-1 Machine. Good for oil reservoir size 750 – 1,000 gallons with water content of 5,000 – 30,000 ppm

- VJ-300 = VJ-300 + FC-4 Machine Machine. Good for oil reservoir size 1,500 – 2,000 gallons with water content of 5,000 – 30,000 ppm

- VJ-300DT = VJ-300 + FC-4 + DT-100 Machine. Good for oil reservoir size 2,000 – 2,500 gallons with water content of 5,000 – 100,000 ppm

- Vacuum Jet Dehydration – VJ-25, VJ-50, VJ-100, VJ-150, VJ-300, VJ-300DT utilizes Atmospheric Air to absorb dissolved water of 2,000 (0.2%) – 50,000 ppm (5%) down to 50 ppm (0.005%) in the oil. MS1 Moisture Sensor is used to control water dehydration and reads water content in ppm and % AW (Water Activity) to assure that the discharged dry oil has water less than 50-100 ppm from Vacuum Jet Dehydrator.

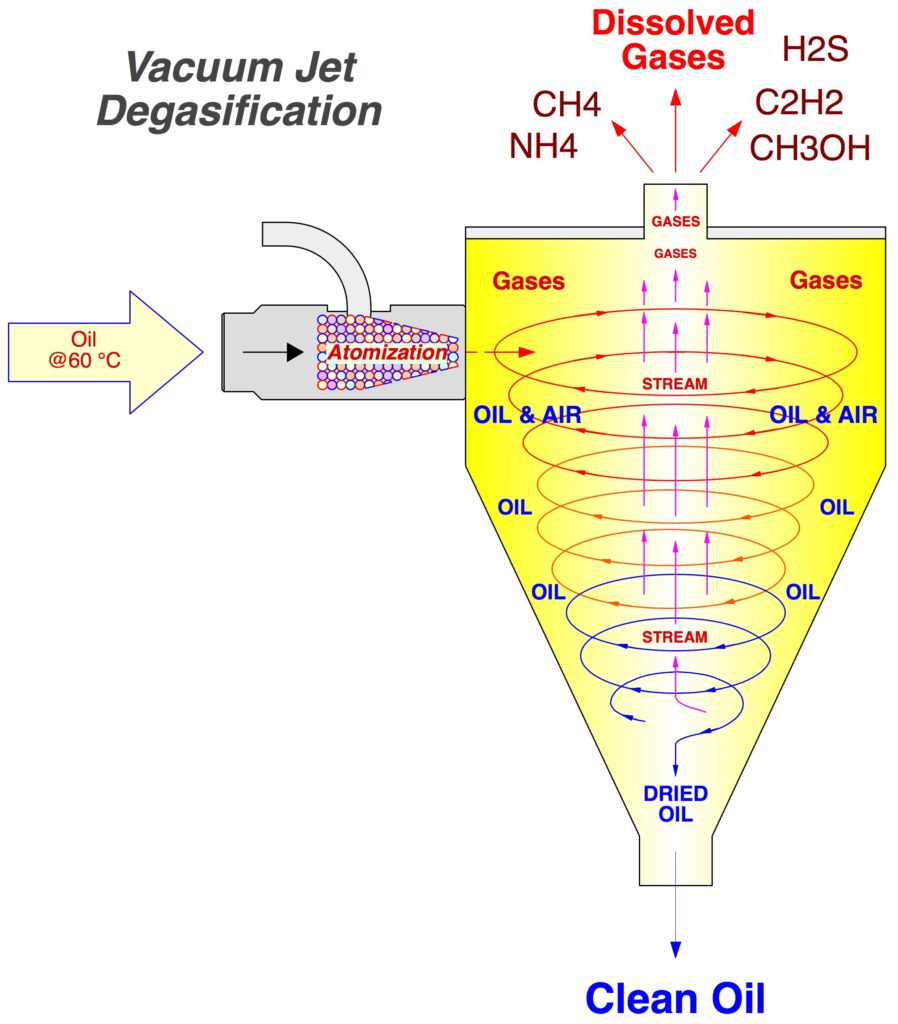

- Vacuum Degasification – Dissolved Gas Removal

- Vacuum Jet Degasification – VJ-50D utilizes Atomization Technology to inflate Dissolved Gases such as CH4 Methane, C2H2 Acetylene, H2S Hydrogen Sulfide, CO2, NH4 etc. to fracture from the oil.

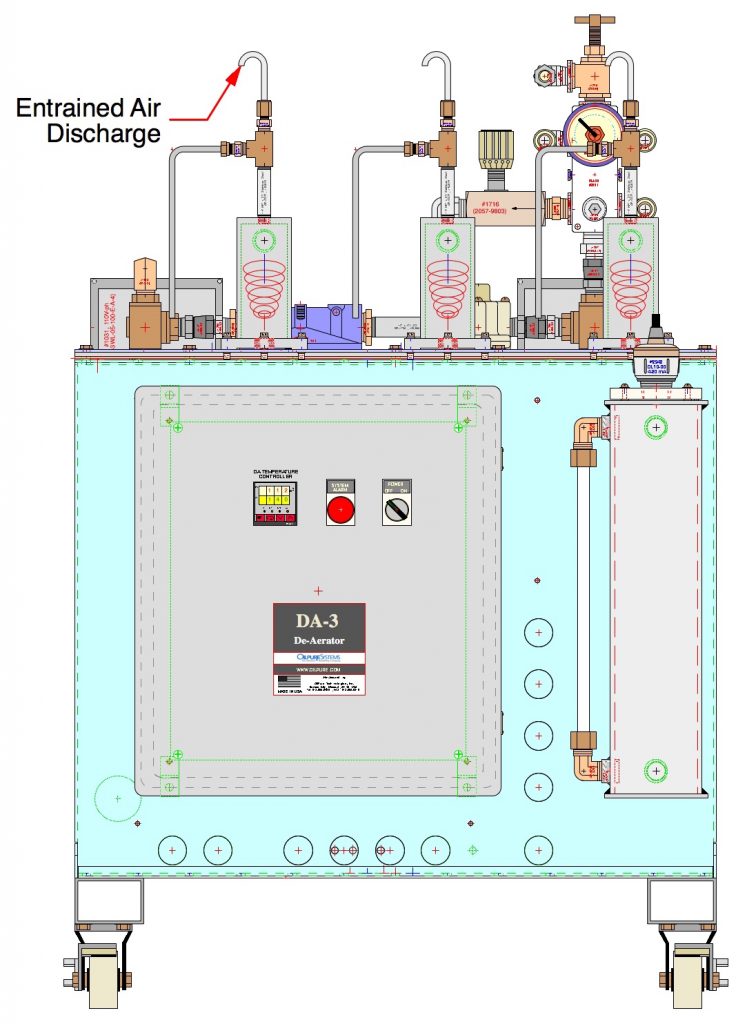

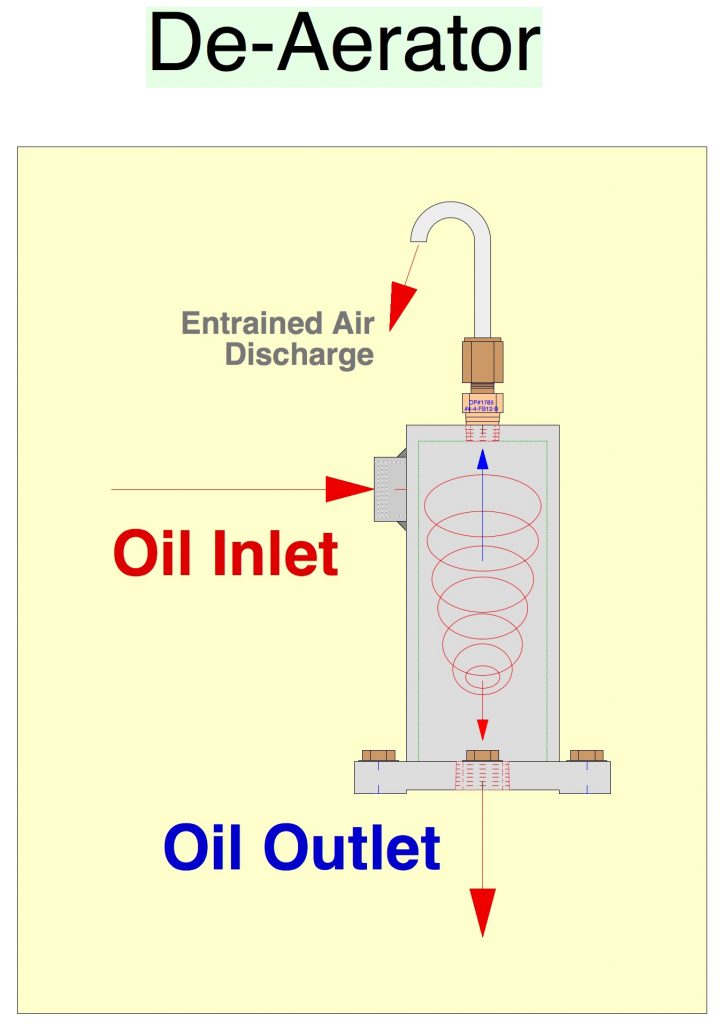

- De-Aerator – Entrained Air & Air Bubble Removal

- De-Aerator – DA-3 removes the visible Entrained Air and Large Air Bubble floating to the top.

- Oil Purifier with PurePack Filtration Technology

- Portable Oil Purifiers – MB-50, MB-50C, MB-50VJ, MB-50VJC utilizes PurePack Chemical Technology to purify the oil at 1-3 microns Solid Particle and removes Dissolved Water, Oxidation By-Products and Oil Acidity from oil with water content up to 1,500 ppm.

- MB-50 Machine Good for oil reservoir size 1,000 gallons

- MB-50C Machine MB-50 + TC-8 (Centrifuge) unit Machine Good for oil reservoir size 1,000 gallons

- MB-50VJ Machine MB-50 + VJD2 (Vac. Jet Degasification) Machine Good for oil reservoir size 1,000 gallons for Diesel Engine Oil from Landfill Gas or Biogas industries.

- MB-50VJC Machine MB-50 + VJD2 (Vac. Jet Degasification) + TC-8 (Centrifuge) unit Machine Good for oil reservoir size 1,000 gallons for Diesel Engine Oil from Landfill Gas or Biogas industries.

- Dedicated Oil Purifiers – SS-50, MB-25, MB-100, MB-150 utilizes PurePack Chemical Technology in the oil purification process.

- SS-50 Dedicated Machine. Good for oil reservoir size 1,000 gallons

- MB-25 Dedicated Machine. Good for oil reservoir size 300 gallons

- MB-100 Dedicated Machine. Good for oil reservoir size 1,500-2,000 gallons

- MB-150 Dedicated Machine. Good for oil reservoir size 2,500-3,000 gallons

- Portable Oil Purifiers – MB-50, MB-50C, MB-50VJ, MB-50VJC utilizes PurePack Chemical Technology to purify the oil at 1-3 microns Solid Particle and removes Dissolved Water, Oxidation By-Products and Oil Acidity from oil with water content up to 1,500 ppm.

- Oil Recycling Machines

- Portable Oil Recycling Machines – AST-25, AST-50, AST-50C

- AST-25 Machine is a combination of VJ-50 + MB-25 + MS1 unit. Recycling capability of 50-100 gallons per day.

- AST-50 Machine is a combination of VJ-100 + FC-1 + MB-50 + MS1 + OS1 MS1 + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 200-300 gallons per day.

- AST-50C Machine is a combination of TC-8 + VJ-100 + FC-1 + MB-50 + MS1 + OS1 + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 150-250 gallons per day.

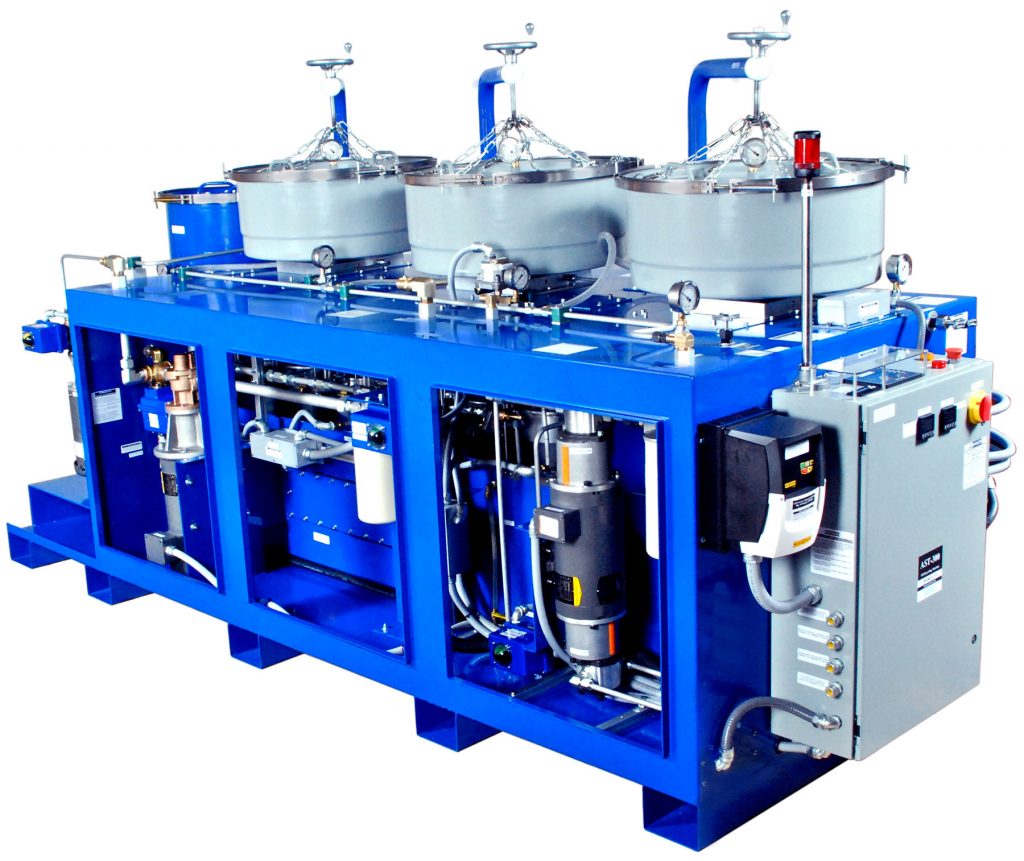

- Large Stationary Oil Recycling Machines – AST-200, AST-300, AST-300-DT, AST-300-OA, AST-300-HT

- AST-200 Machine is a combination of VJ-150 + FC-1 + MB-100 + MS1 + OS1 + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 400-500 gallons per day.

- AST-300 Machine is a combination of VJ-300 + FC-4 + MB-150 + MS1 + OS1 + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 600-800 gallons per day.

- AST-300-DT Free Water Separation Machine is a combination of DT-100 + VJ-300 + FC-4 + MB-150 + MS1 + OS1 + OA1 + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 500-700 gallons per day.

- AST-300-OA On-Line Oil Analyzer Machine is a combination of VJ-300 + FC-4 + MB-150 + MS1 + OS1 + OA1 + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 600-800 gallons per day.

- AST-300-HT High Temperature Machine is a combination of FC-4 + MB-150 + OS1 + OA1 + Heat Exchanger + WebMI Remote Control + Mini SCADA Unit. Recycling capability of 500-700 gallons per day.

- Portable Oil Recycling Machines – AST-25, AST-50, AST-50C

- C Series Cartridge Pre-Filtration

- FC-4 Cartridge Filter Unit with 4 filter elements

- FC-1 Cartridge Filter Unit with 1 filter element for built-in Pre-Filtration in AST-50 unit

- C-5 for 5 Micron Filter – 6.50″ dia x 30″L cartridge filter element for FC-1 or FC-4 Filter Unit

- C-12 for 12 Micron Filter – 6.50″ dia x 30″L cartridge filter element for FC-1 or FC-4 Filter Unit

- C-24 for 12 Micron Filter – 6.50″ dia x 30″L cartridge filter element for FC-1 or FC-4 Filter Unit

- Oil & Water & Oxidation & Particle Count Sensors & Machine Conditioning

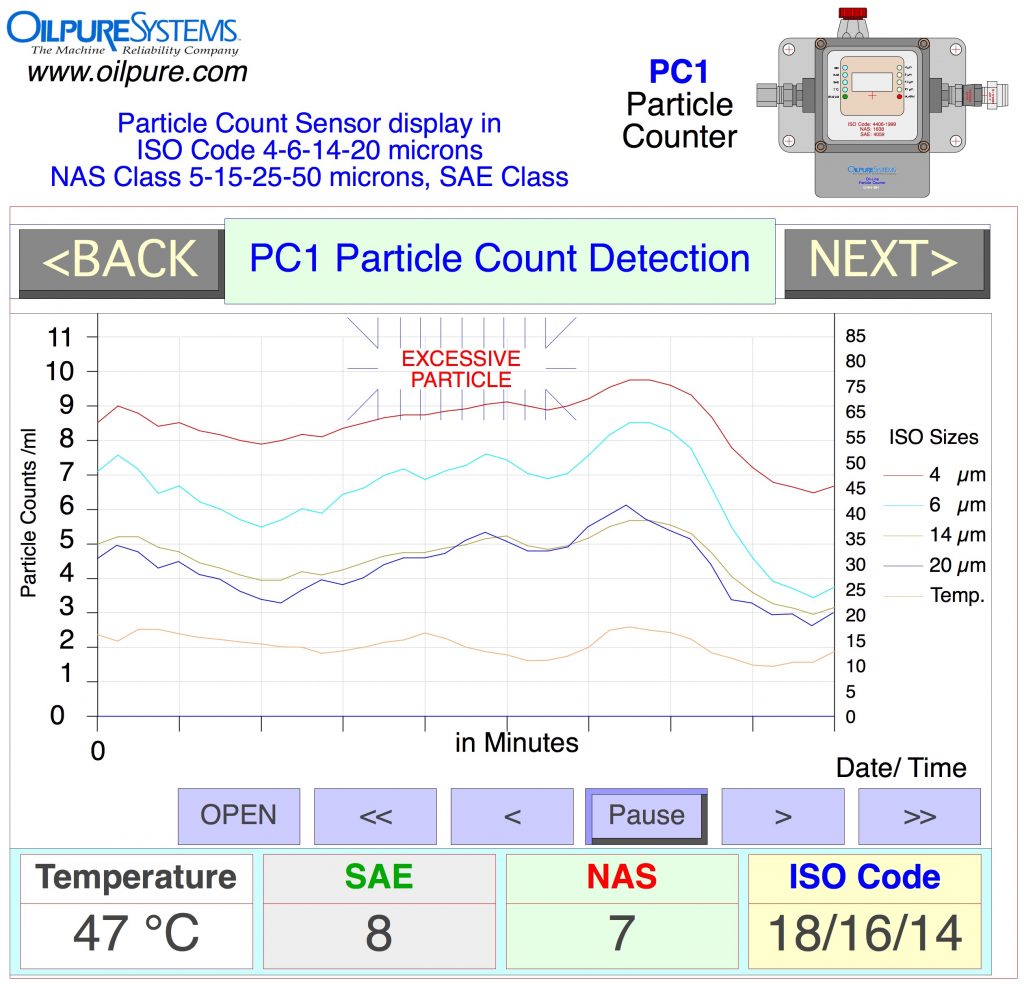

- PC1 Particle Count Sensor – reads solid particle size 4 – 6 -14 micron sizes in ISO Code and NAS Class

- MS1 Moisture Sensor – reads water in ppm and % AW (Water Activity)

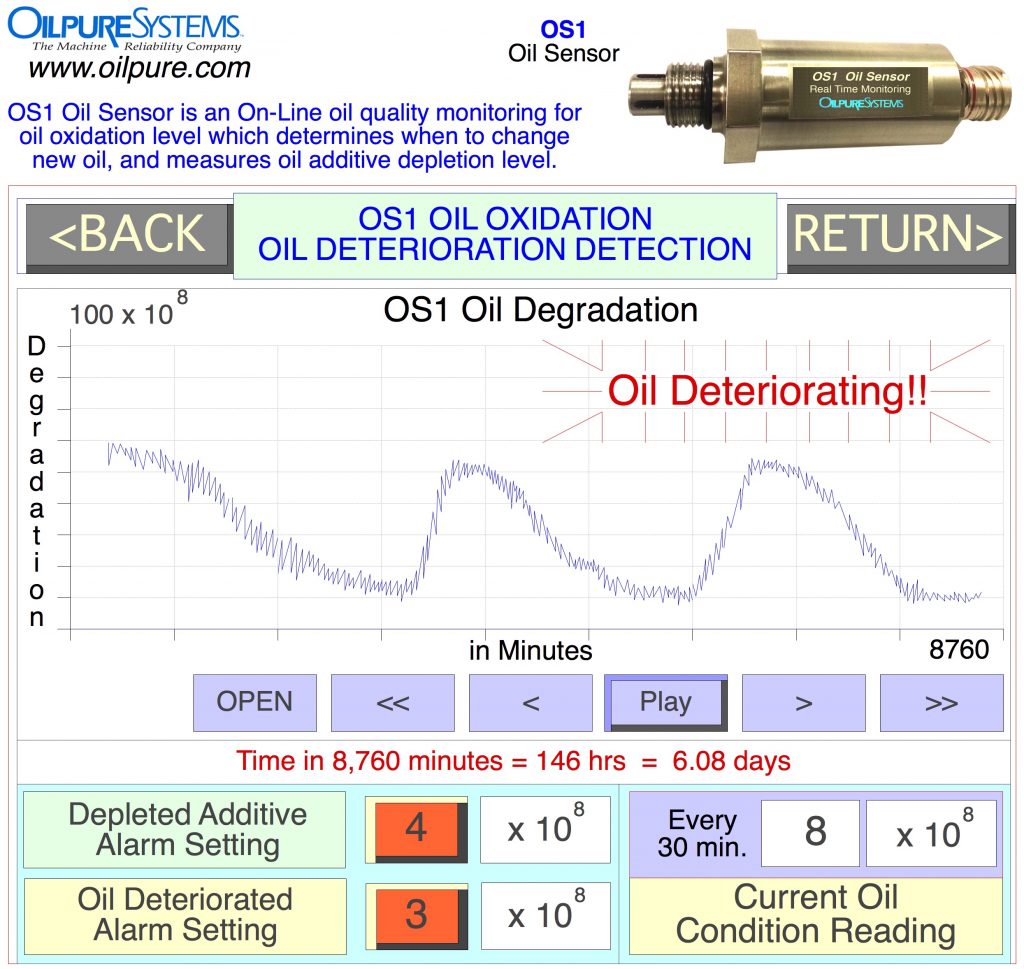

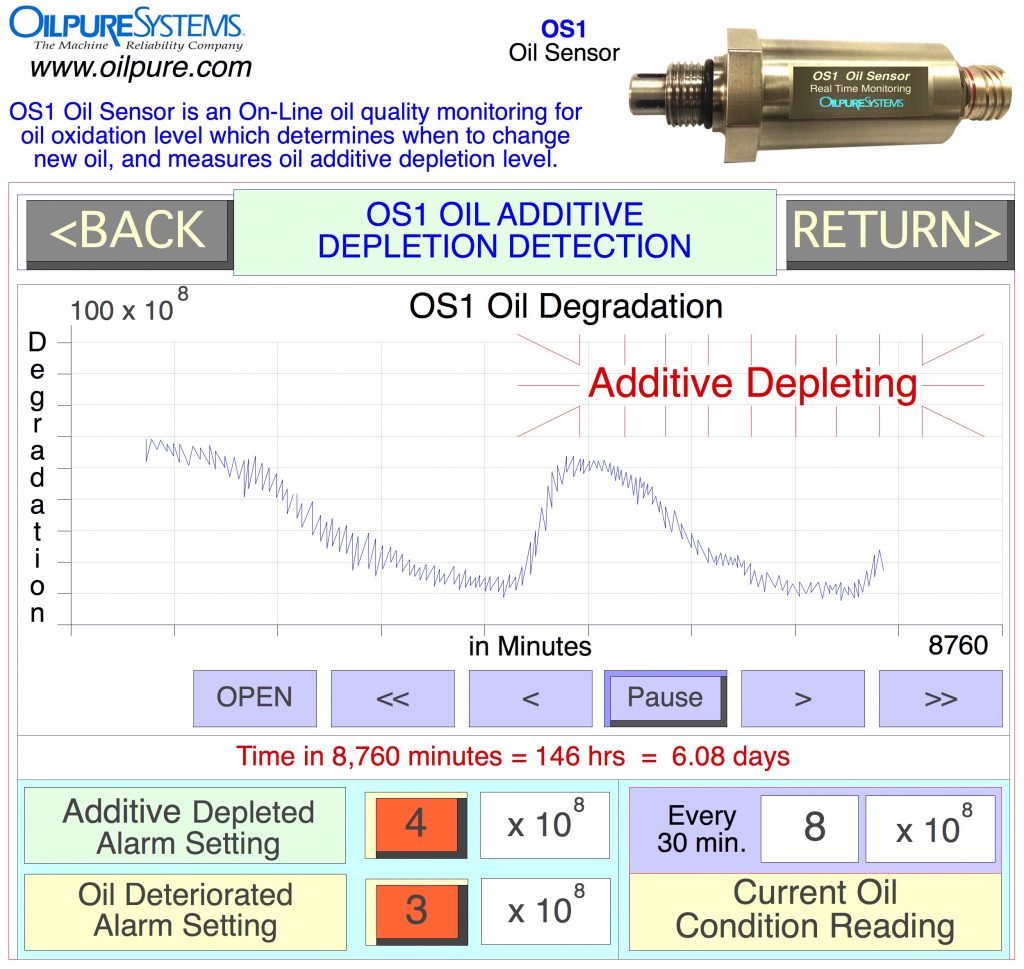

- OS1 Oil Sensor – reads the changes in oil oxidation and oil additive depletion

- TH1 Oil temperature – reads oil temperature in various locations of the machine to determine hot spots.

- Other sensors monitoring the machine condition such as Vibration Sensor, Tachcometer, Ultrasonic Level Sensors, Color Sensor etc.

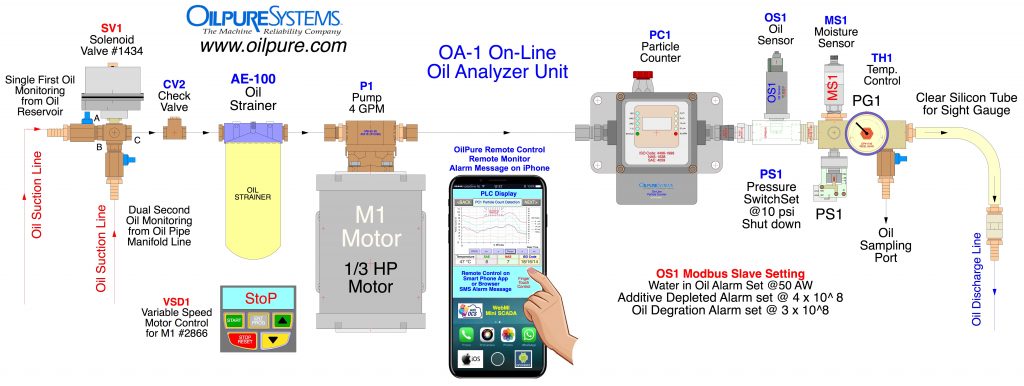

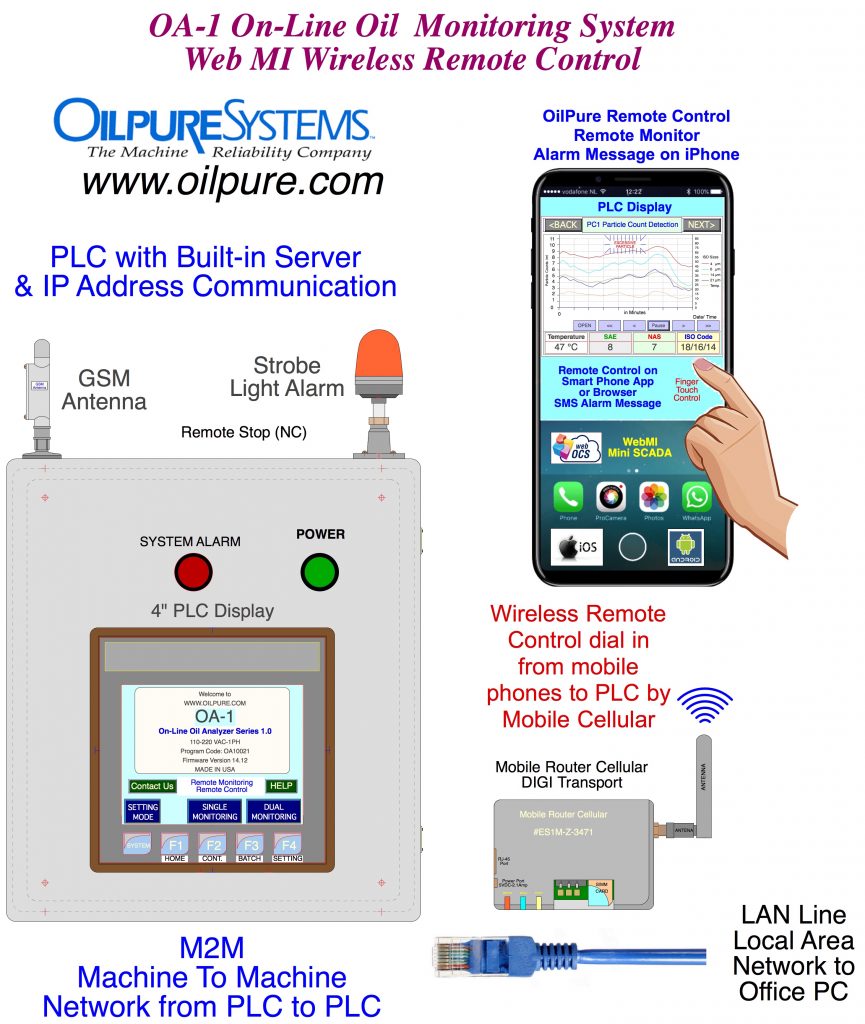

- OA-1 OnLine Oil Analyzer

- OA-1 – On-Line Oil Analyzer unit measures PC1 Particle Sensor in NAS & ISO Code, MS1 Moisture Sensor water in ppm, OS1 Oil Sensor for Oil Oxidation & Additive Depletion, TH1 Oil Temperature. Oil Analysis result transmits through Static IP Address SIMM card. Alarm message sends by e-mail & SMS text message directly to user’s smart phone. User can dial in to view oil analysis result from smart phone App outside the plant.

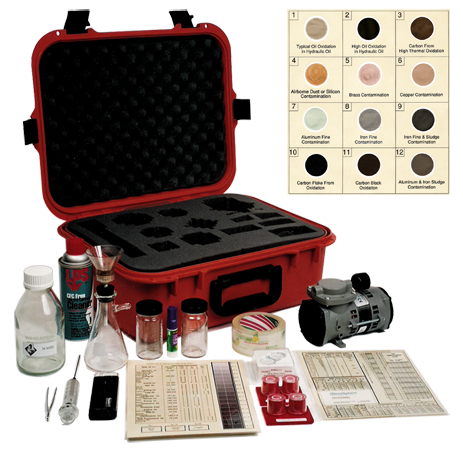

- Oil Test Kits

- DOT Test Kit – measures solid particulate at 0.8 – 5 – 12 micron level

- TAN Test Kit – measures oil acidity in TAN Total Acid Number

- Oil Additive Mixer – Model: AP-55

- Oil Additive Refortification – Supplemental Oil Additives (SAR)

- Antiwear (AW)

- Extreme Pressure (EP)

- Antioxidant (AO)

- Corrosion Inhibitor (CI)

- Anti Foaming (AF)

- Demulsifying Agent (DA)

- Viscosity Improver (VI)

- Friction Modifier (FM)

- Dispersant

- TBN Total base Number

Detect Oil Oxidation & Oil Additive Depletion

Read Water Content in ppm & Monitor Dehydration Process

PC-1 displays NAS, SAE and ISO Code ISO-4406

Oil Oxidation Trend Reading

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815 • WhatsApp: 1-913-522-0272

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.