2.1.7 Failure of Toilet Paper Filter

This type of depth paper filter is made of cellulose paper material wound into central core in the same way toilet paper is made. The cellulose paper is condensed and unbleached in an attempt to trap small particle. Cellulose material is made of the similar to toilet paper or kitchen paper towel with more condensed pack.

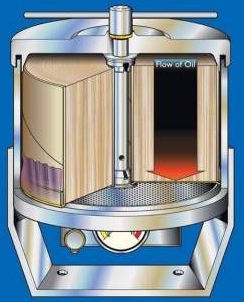

Dirty oil penetrates from top down passing through axial flow of paper line. Filter media can be stacked into 2 or 3 layers on top of each other into a cartridge filter housing.

It is a by-pass filter type that draws dirty oil from hydraulic valve manifold or its own gear pump, delivering dirty oil through the filter media. The resistant oil pressure from 4.50″ Thick depth filter media is about 40 psi. Oil is either pressurized and flowed from hydraulic system oil pressure from valve manifold or its gear pump. Oil is delivered directly through filter media from top down and clean oil is discharged from the bottom of filter media. Contamination is absorbed inside its cellulose paper media. The filtration capability is totally depending on its Cellulose Capability and Media Integrity.

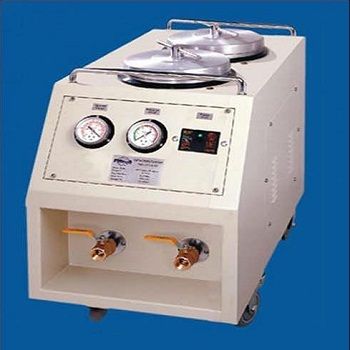

Typical multiple stack toilet paper filter media with stand alone pump unit.

Toilet Paper Media Integrity Effected by the Following Variables:

- Water content larger than 500 ppm

- Oil temperature higher than 160 °F (71 °C)

- Oil pressure surge flowing from hydraulic valve manifold during hydraulic power cycle

Faulty filtration claims from this toilet paper filter type which is unable to achieve. Here is why:

- Remove Oil Oxidation & Reduce Oil Acidity (Total Acid Number)

- Cellulose is unable to remove or reduce Total Acid Number (TAN).

- Cellulose is not capable of chemical bonding to polymers such as oxidation by products or acidity which is occurred by chemical reaction, not physical action.

- Cellulose only reacts to oil contamination on the physical barrier, but has no chemical reaction capability to pull out acids such as Carboxylic acid and Lewis Acids (Having Hydrogen molecule inside) from oil. This is a faulty claim on acid removal.

- This Polymer or Oxidation by products or Varnish (not the Acid) become dissolved in the oil temperature over 160 °F (71 °C), Polymers become Wax products dissolving in the oil which is unable to physically be filtered out from oil by Physical Barrier Filter.

- However when the oil temperature is less than 100 °F (38 °C), about 10%-20% of Polymer becomes thickening as Wax and can be easily filtered out by physical barrier filter such as cellulose paper. Not all Polymer will be filtered or removed by physical barrier filter. It is only half truth that Toilet Paper filter can remove Oil Oxidation, Varnish and Acidity in the oil.

- Some oil testing shows small TAN reduction by cellulose filter because the sludge in the oil is trapped in the cellulose media. This sludge has acidic value. When this acidic sludge is removed from oil, oil acidity can decrease slightly. But not enough to chemically counteract or neutralize the acid molecule in the oil.

- Remove Dissolved Water or Free Water

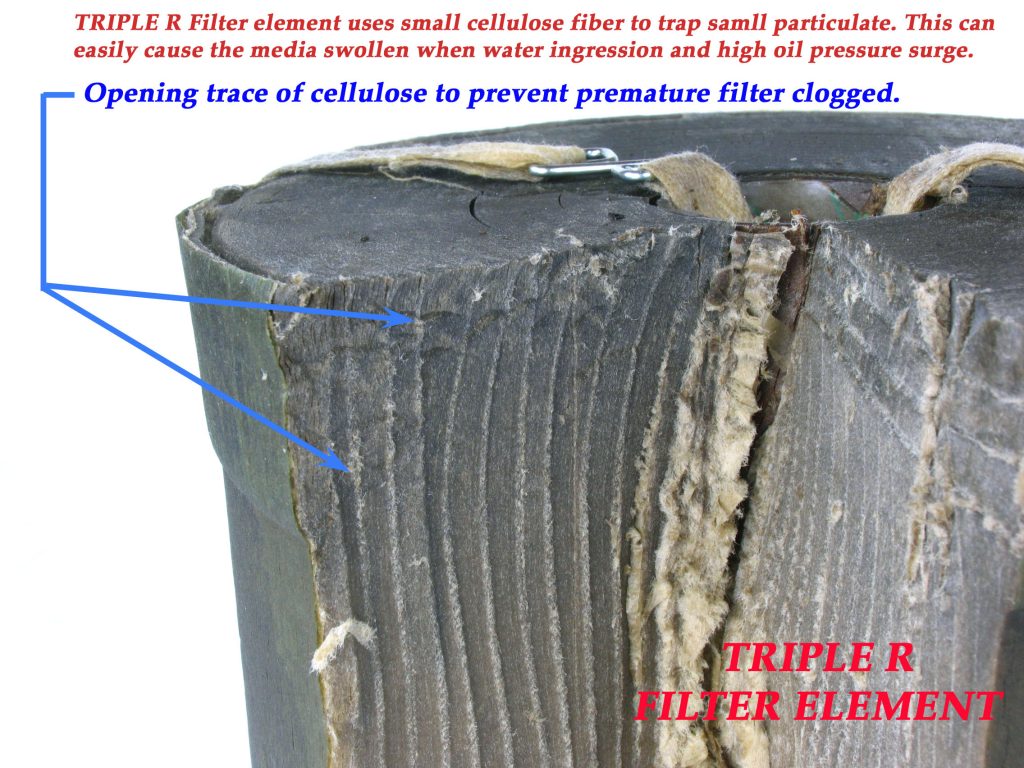

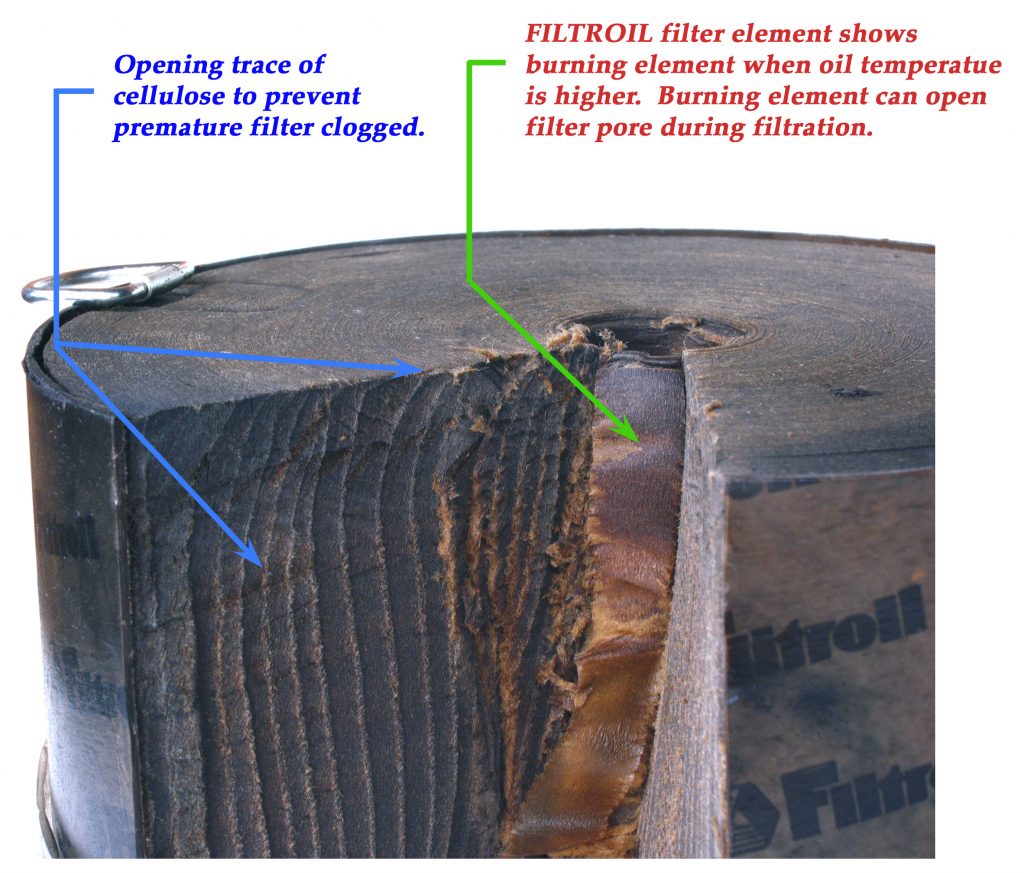

- By nature cellulose can absorb water and hold inside the cellulose structure. When water is more than 500 ppm in the oil, water will migrate from oil to cellulose and the cellulose structure starts to expand or become swollen.

- The change in cellulose structure with water will open and enlarge the cellulose pore structure. After cellulose swells, it will lose the solid particle retention and filtration capability.

- Small particle will start to migrate out of cellulose media from discharge side. This means that it is no longer hold on the oil contamination as advertised.

- Toilet Paper Filter only works good when water in the oil is less than 500 ppm.

- Remove 0.2 micron Solid Particle from Oil

- It is that fact that a typical cellulose media material is unable to remove solid particle less than 10 micron level. The cellulose nature just doesn’t have the low micron particle retention capability.

- This is why all of the less than 10 micron paper filter is made of synthetic fiber such as polyester, rayon etc. The depth cellulose media only helps more Dirt Holding Capacity, not the low micron retention capability.

- This can be explained that good paper filtration media such as Pall or Hydac filters with typical 6 micron retention, is never made of cellulose material.

- Toilet Paper Filter can only works well with small low pressure hydraulic systems. It is not suitable for high speed large hydraulic system having larger than 100 ton which its servo valve or proportional valve require much lower than 10 micron filtration rating.

- So it is impractical that cellulose filter media can remove solid particle to 0.2 micron as promised.

Oil Filtration Problems with Toilet Paper Filter

- Oil pressure surge in the filter media causes dirt blow-by migrating out of media when oil contamination starts to fill up the entire media. High oil pressure is not the cause of dirt migrating problem, but oil pressure surge does have the negative effect. During hydraulic power transmission cycle dropping from 3,000 psi to 40 psi of oil pressure, oil pressure surge will tweak and puncture cellulose filter media.

- High oil temperature higher than 160 °F (71 °C) will start to cook and fry cellulose media. Cellulose media will become brittle and crack. This changing in media integrity will open cellulose pores and allows unclean oil passing through the media. Cellulose media becomes fouling.

- Water content higher than 500 ppm will swell the cellulose layer and open cellulose pores because cellulose nature will absorb water. Water inside cellulose media will wreck the cellulose integrity and media becomes fouling. Try drop a toilet paper in the water at home. You will notice the wrinkle on toilet paper media.

- Solid particle can only be removed effectively in a few hours or a few days after new filter element was installed. After dirt starts to trap inside cellulose media, the micron rating will drop dramatically. It will not continue filtering minute particle effectively through out the life of filtration as advertised.

- Cellulose media filter will continue decline from Absolute Value to Nominal Value filtration rating. Solid particle filtration will continue to decline during the life of filtration.

The above information is based on our experiences with users and their comments who wishes the manufacturer can improve their products. Please review with good discretion.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • SKYPE ID: oilpure • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • Fax: 913-906-9815 • WhatsApp: 1-913-522-0272

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.