2.1.4 Failure of Electrostatic Oil Cleaner (EOC)

Problem of Electrostatic Oil Cleaner (EOC)

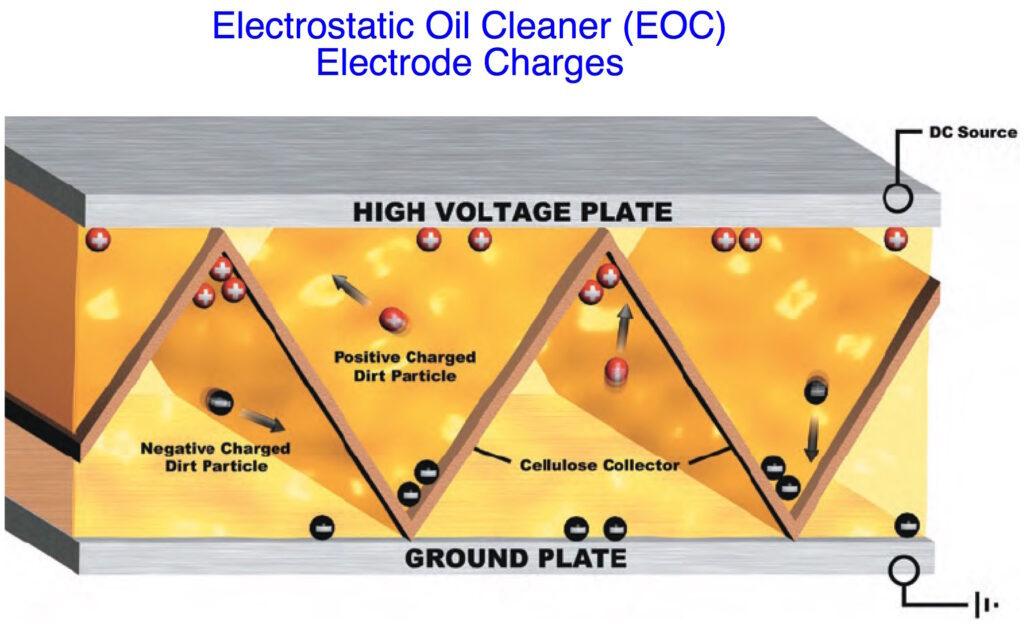

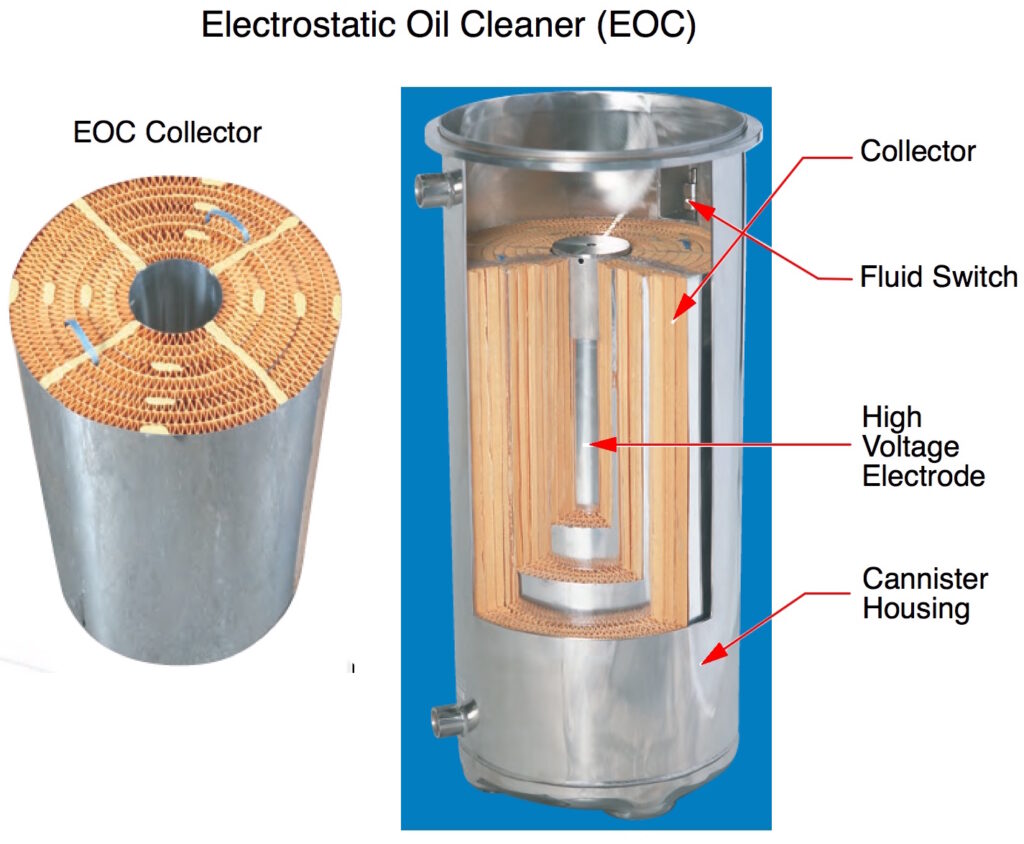

Electrostatic Oil Cleaner (EOC) removes solid particulate by using Electrostatic Precipitation to cluster Sub micron Dust Particle (insoluble silicon dust) into larger particle through + Charge and – Charge attraction. This small Insoluble Particle will be clustered on the Electrodes and collected in the Impregnated Cellulose Filter. Varnish and Oxidation-by-Products are also attractive to these charges and will be trapped on EOC Collector. This varnish makes it difficult to clean the EOC Collector. EOC Collector new replacement can be expensive.

Electrostatic Oil Cleaner (EOC) can trap Varnish from oil but has no effect on Oil Acidity (TAN – Total Acid Number) which is a Root Cause of Oil Oxidation. Oil Acidity is the Input while the Oxidation or Varnish are the Output. Varnish will return if Oil Acidity is still not under controlled.

Electrostatic Oil Cleaner (EOC)

Disadvantages of Electrostatic Oil Cleaner (EOC)

- EOC is very efficient in trapping Silicon Dust Particle due it Attractive Particle Charges, but merely trapping Metallic Wear Particles such as Fe Iron, Cu Copper, Al Aluminum etc. Most oil contamination contains both Silicon Particulate and Metallic particulate. EOC is not enough to take control for all solid particle contamination.

- EOC will not work on oils having more than 500 ppm of water. This water will cause Arcing or short circuit between Electrode and shut down in EOC. Water Eater is used as Pre-Filter to trap water before oil enters to EOC to avoid this arcing. When Water Eater is saturated, it will allow water to migrate into EOC and cause a voltage drop in Electrode Charges. Most trapped particles will migrate through EOC Collector if voltage drop is not fast enough to shut down the EOC unit. This Water Eater is made of Desiccant of High Molecule Weight Chemical or the same material that is made for baby diaper.

- EOC can remove Oxidation-by-Products such as Varnish due to its Free Radical Attraction with Electrode. However, EOC has to run 50-100 passes of oil flushing in order to elongate Varnish and Dust Particle to become a cluster so it can be trapped in the EOC Collector. This makes EOC a Low Filtration Efficiency.

- EOC is unable to reduce TAN Total Acid Number which is a Root Cause of Oil Oxidation Reaction in the oil. Varnish may be removed out today but it will come back again in 2-3 months because Oxidation Reaction from oil acidity still continuously occurs in the oil. Oxidation can be controlled when TAN is not higher than 10%-25% from new oil.

- EOC Collector has limited Dirt Holding Capacity. When there is more Varnish than Silicon Particulate, EOC Collector will clog prematurely and need a new replacement or clean up. This requires precision skills to work on the Cellulose Pack Coil in the Collector and makes it more difficult to clean up.

The above information is based on our experiences with users and their comments who wishes the manufacturer can improve their products. Please review with good discretion.

- Contact Information – OilPure Technologies, Inc.:

- P.O. Box 483976 • Kansas City • Missouri 64148 • USA • LINE ID: oilpure

- Tel: 913-906-0400 • Mobile: 913-522-0272 • WhatsApp: 1-913-522-0272 for International call

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.